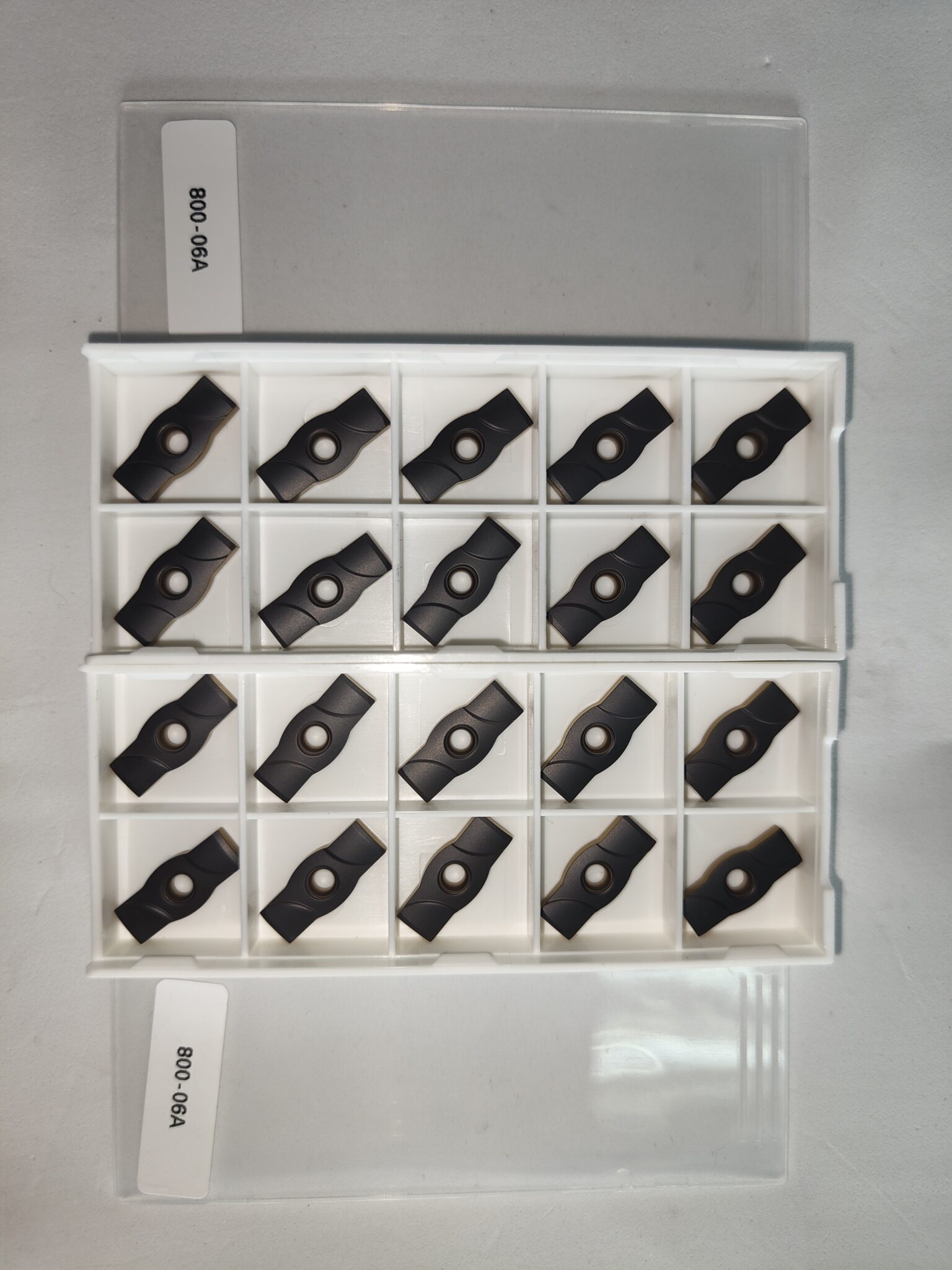

sandvik deep hole guide pads

Sandvik deep hole guide pads

When it comes to deep hole drilling, Sandvik deep hole guide pads stand out as a reliable solution for achieving precision, stability, and efficiency. Designed to meet the demands of challenging drilling applications, these guide pads are engineered to enhance performance and deliver exceptional results. Here’s why deep hole guide pads are a top choice for professionals in industries like automotive, and oil and gas.

Contact us +8618353452290,sales@btadrilltools.com

800-06A,800-08A,800-10A,800-12A,800-14D ,800-16D,800-18D085,800-20D,800-26D,430.32-16D

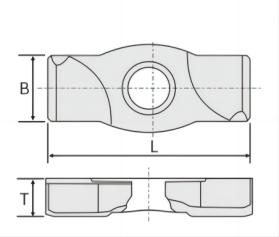

Type |

Diameter range |

L |

B |

T |

800-06A | 25.00-31.00 | 18 | 6 | 3.0 |

800-07A | 31.01-39.60 | 20 | 7 | 3.5 |

800-08A | 39.61-47.00 | 25 | 8 | 4.5 |

800-10A | 47.01-54.99 | 30 | 10 | 4.5 |

800-12A | 55.00-65.00 | 35 | 12 | 5.5 |

800-14D | * | * | * | * |

800-16D | * | * | * | * |

800-18D085 | * | * | * | * |

800-20D | * | * | * | * |

800-26D | * | * | * | * |

430.32-16D | * | * | * | * |

Key Features of sandvik deep hole guide pads

1. **Superior Coating Technology**

– Equipped with advanced coatings that enhance wear resistance and extend tool life.

– Reduces friction and heat generation during drilling, ensuring smoother operations.

2. **Exceptional Stability and Precision**

– Designed to provide optimal support for deep hole drilling tools, minimizing vibrations and deflection.

– Ensures straight and accurate holes, even at greater depths.

3. **High-Quality Materials**

– Made from durable materials that withstand high-pressure and high-temperature conditions.

– Offers excellent resistance to wear and corrosion, ensuring long-lasting performance.

4. **Improved Cutting Performance**

– Optimized geometry enhances cutting efficiency, even in tough materials like stainless steel, titanium, and high-temperature alloys.

– Delivers consistent results with minimal tool wear.

5. **Versatility**

– Compatible with a wide range of deep hole drilling machines and setups.

– Suitable for various industries, including aerospace, automotive, and oil and gas.

6. **Extended Tool Life**

– Durable construction and high-quality coatings reduce the need for frequent replacements, lowering overall tooling costs.

7. **Critical Role in Deep Hole Drilling**

– Provides essential support to the drill bit, ensuring stability and precision throughout the drilling process.

– Ideal for applications requiring high accuracy and reliability.

8. **Efficient Supply Chain**

– ensure short delivery times, helping manufacturers meet tight production schedules.

Why Choose deep hole guide pads?

Deep Hole Guide Pads combine cutting-edge technology, robust design, and quick delivery to meet the demands of modern manufacturing. Their superior coating, exceptional cutting performance, and critical role in deep hole drilling make them an indispensable tool for achieving precision and efficiency.

Upgrade your deep hole drilling operations with Deep Hole Guide Pads and experience unmatched performance. Contact us today to learn more about how these innovative tools can enhance your productivity and deliver exceptional results!