Gun Drilling Drill Head

We focus on gundrill production business.

We supply high quality gundrilling drill head

(1) brazed single blade gundrill drill head

(2) Single flute solid carbide gundrill drill head

(3)Indexable gundrill head

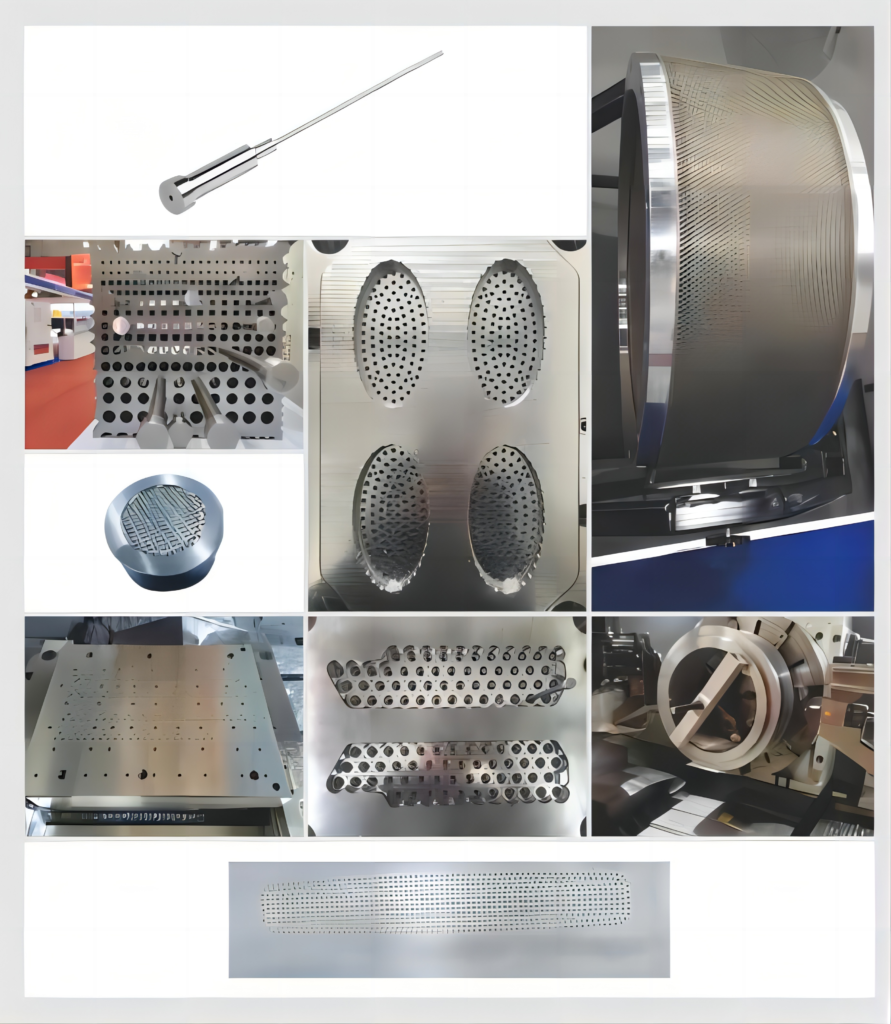

1.Product Display

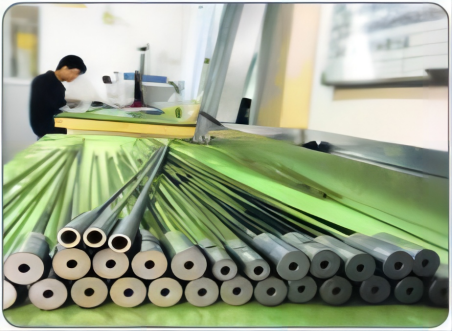

We are china manufacturer of gun drills drill head, located in Dezhou, Shandong which is a base city for deep hole drilling. We can produce many sizes of gun drills as well as non standard gun drills according to clients’ special requirements.

We focus on gun drill production business. We have special deep hole drilling tool machines. Our gun drill carbide tip (brand ESTECH) is sourced from Switzerland, which guarantees the quality of the tool. ESTECH was founded in 1941, is a partner of Botek.

Our company invites famous cutting tool professors in this industry to instruct the research and development. With many years development, we have our own technique process, and registered our own brand. Nowadays,our products are sold well in domestic market and overseas,and are highly praised by our customers.

As a good private owned company, we have innovative, capable and flexible structure, and complete and scientific quality control system. Our gun drills are high hardness, good rigidity, high accuracy, long lasting, and good cost performance.

Continuous improvement of the process, solid progress to produce the gun drills, creating a national brand, and to pursue the excellence is our eternal goal.

professors in this industry to instruct the reserach and development. With many years development, we have our own technique process. Our products are sold well in domestic market and overseas and are highly praised by our customers.

Our gundrills are high hardness, good rigidity, high accuracy, long lasting, and good cost performance.

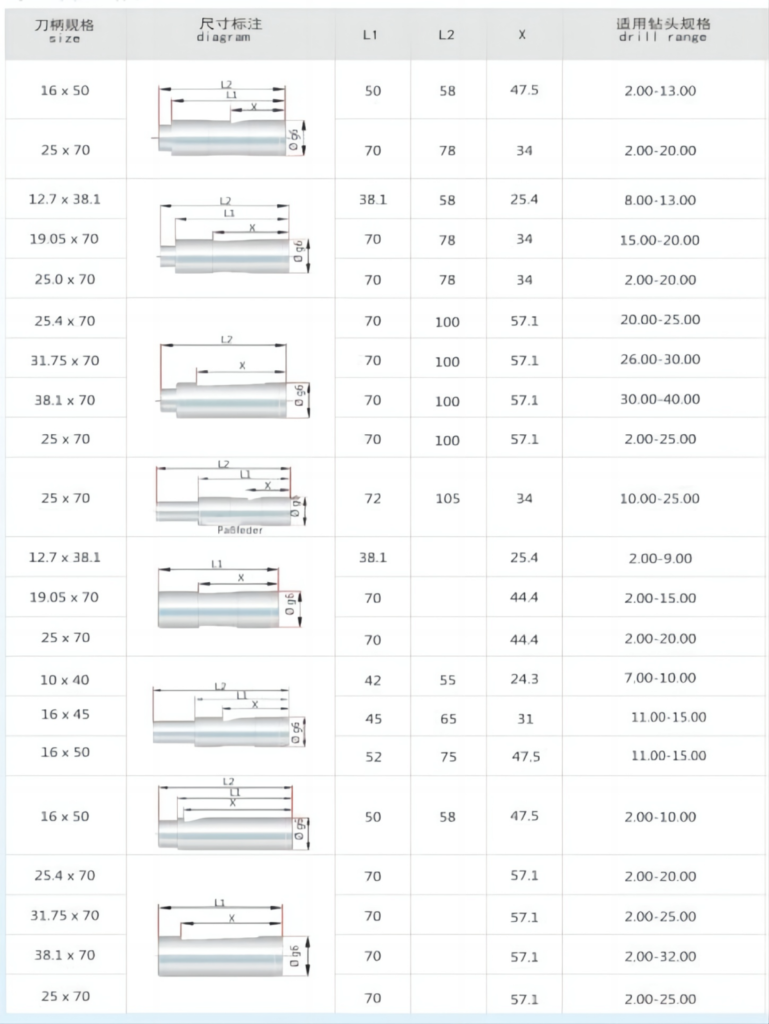

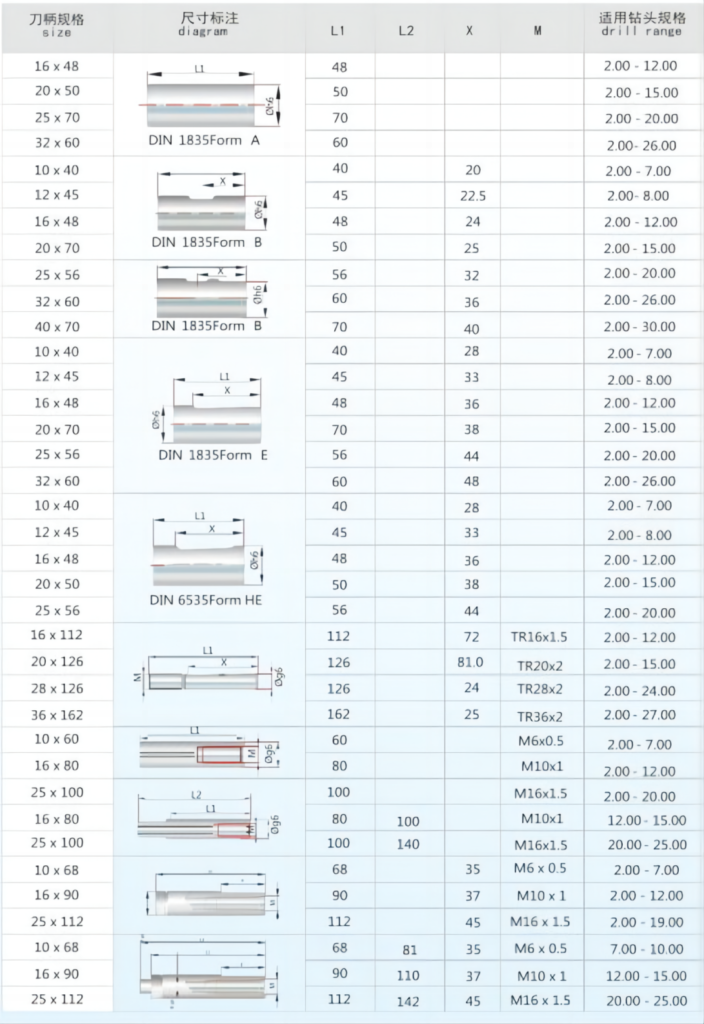

2.Brazed single blade gundrill drill head Drivers

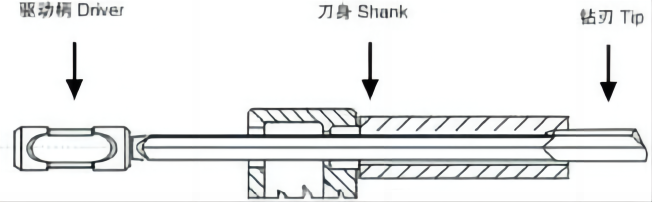

3.Brazed gun drill structure

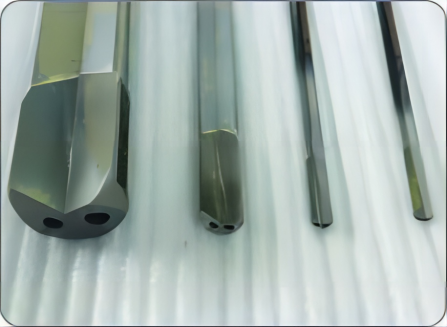

As a key part to the gun drill, Drill Edge guarantees cutting and self-guidance by its specifically scientific combination structure to drill a highly precise hole by one-time penetration. Drill edge has two basic parameters. On the basis of the parameters, the best combination can be selected according to workpiece material and form for better balance between cutting force and chip breaking and transferring cutting force to support shoulder with the aim of good straightness and coaxiality. Drill tip can make drill body rotates freely without friction against internal hole wall. According to different requirements, the edge has single circular hole, kidney-shaped hole and double-circular holes with channels connected to oil passage of the tool blade so that high-pressure coolant travels through the passage to the cutting point and removes chips.

Shank is made of special aviation alloy steel through heat treatment. The blade has a 115-165°V-shot where high -pressure cutting fluid passes through driven handle and oil hole to be drained away with chips.To guarantee cutting straightness and coaxiality, the blade shall be strong enough to provide the torque needed by cutting under small twist deformation; meanwhile, it shall be tough to absorb vibration resulted from high-speed blade rotation.

Driven Handle transfers torque between machine tool and drill bit; high-rotation precision between drill handle and stem avoids extra vibration to improve precision and reliability. Our gun drill is fabricated entirely in accordance with standardized machining. Its neck with the blade has a smooth arc slot to remove stress for avoiding damage due to stress concentration.

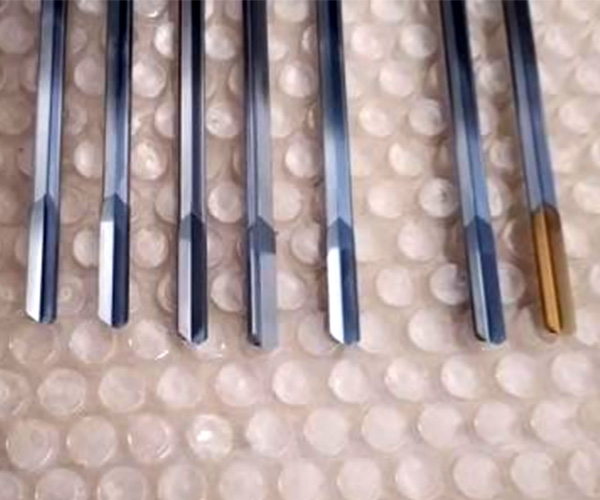

4.SINGLE FLUTE SOLID CARBIDE GUN DRILL

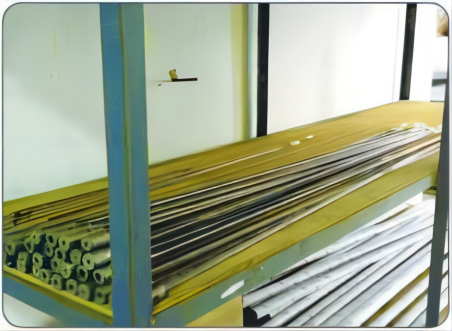

5.workshop picture