Hydraulic Pile Breaker

Hydraulic Pile Breaker

High efficiency, fast speed, and labor saving in pile breaking!

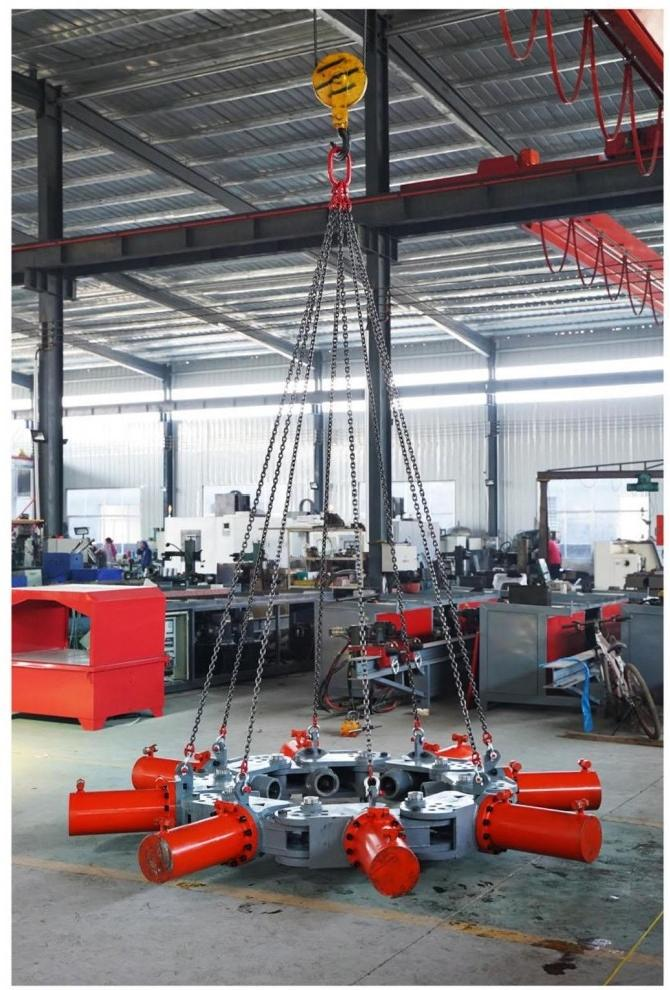

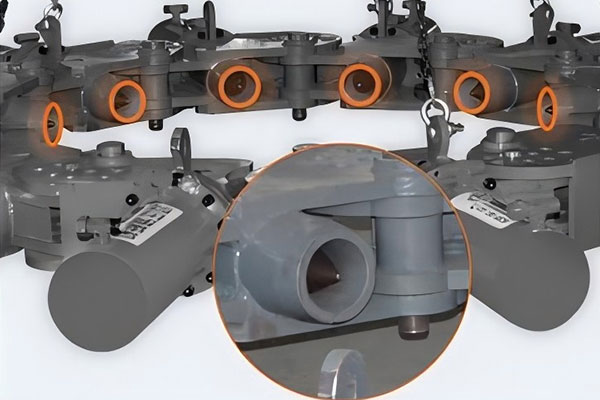

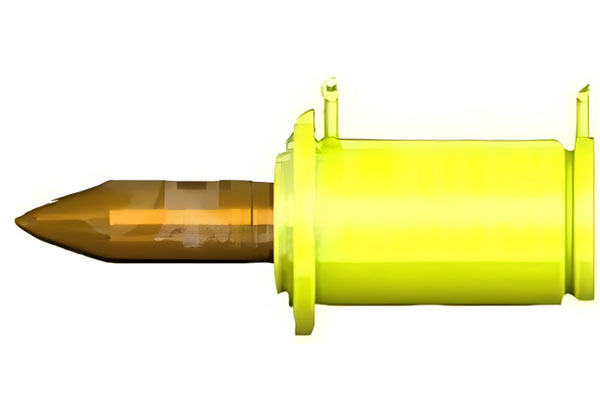

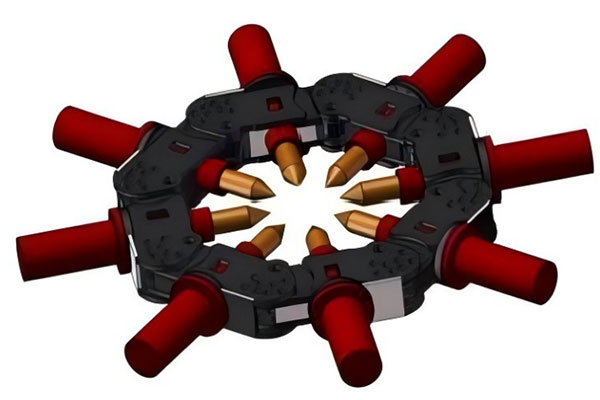

The hydraulic pile breaking machine provides pressure to multiple oil cylinders of the pile cutting machine through a power source. The oil cylinders directly drive the drill rod, while squeezing the pile body to cut off the pile head. During the construction process of the pile breaking machine, it is easy to operate, efficient, low noise, and cost-effective, suitable for pile group construction projects. The pile breaking machine adopts a highly modular combination, which is connected to modules through a pin shaft. By combining different numbers of modules, a certain range of diameter pile heads can be cut off.

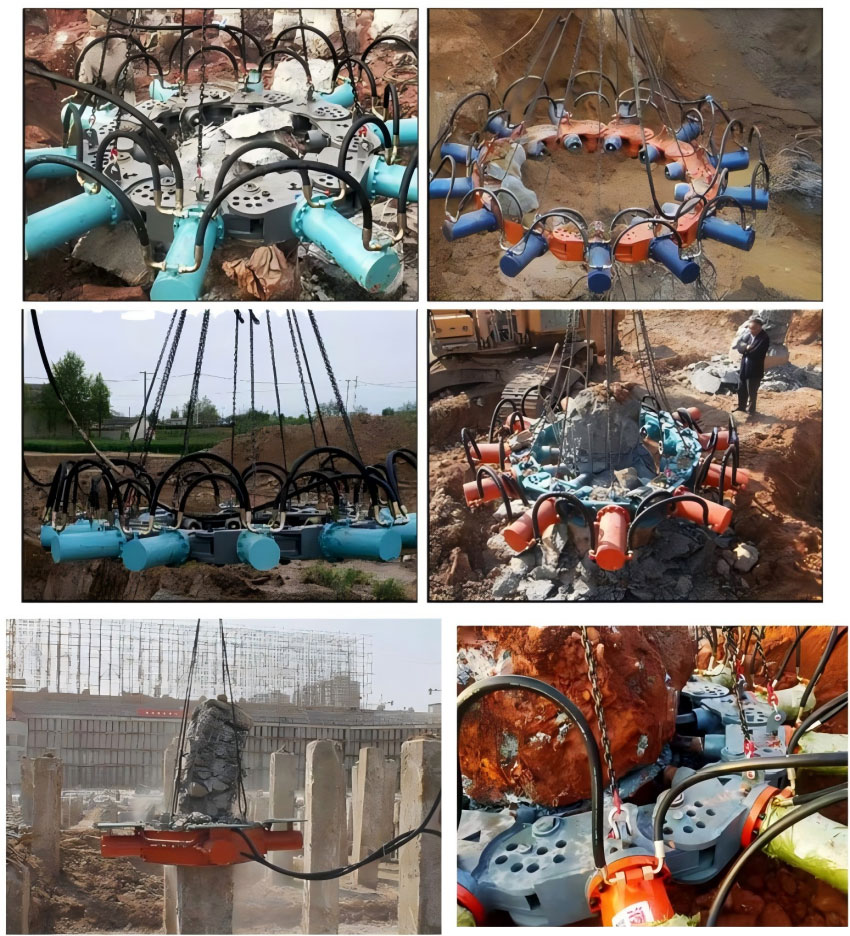

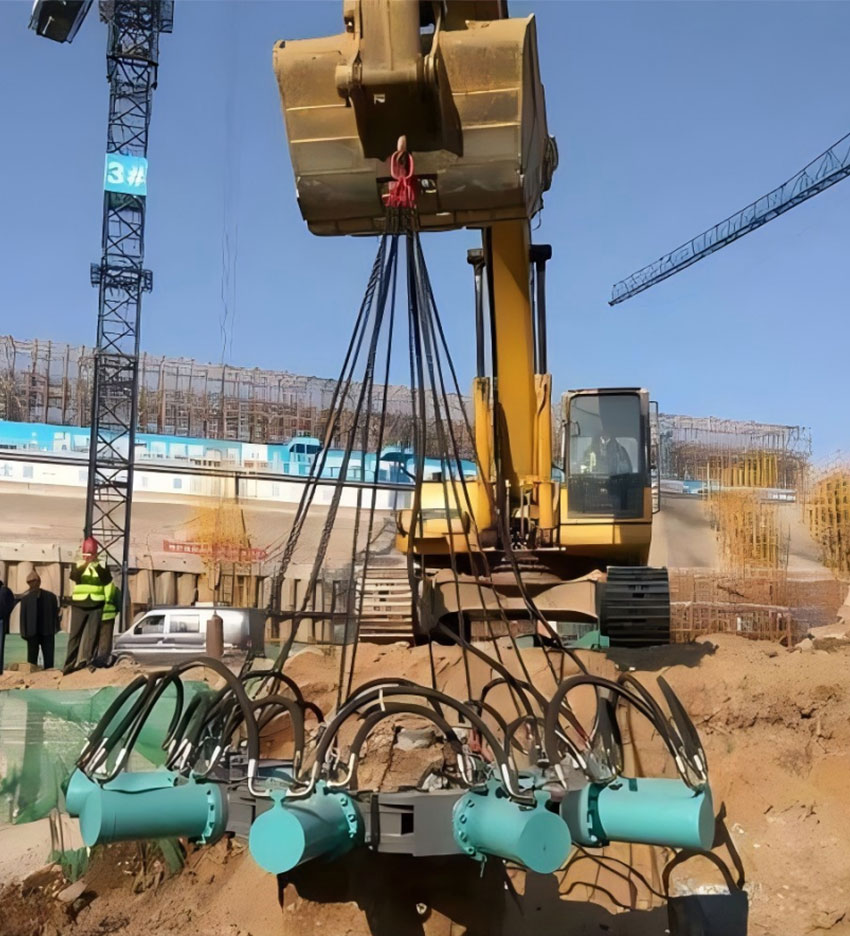

Hydraulic pile breaking machine for cutting: such as cast-in-place piles, prefabricated piles, etc. Pile breaking machines are widely used in high-speed railway bridges and civil engineering pile foundation projects.it can meet the requirements of various large-scale foundation construction.

We produce hydraulic pile breaker, if you need, please contact us email: sales@btadrilltools.com ,whatsapp +8618353452290

The Advantages and Applications of Hydraulic Pile Breaker

In the field of construction and engineering, the hydraulic pile breaker has emerged as a game-changer. This powerful tool is designed to efficiently break down concrete piles, offering numerous benefits and applications.

The hydraulic pile breaker operates on the principle of hydraulic pressure, which provides immense force to crack and split concrete piles. It is a highly efficient alternative to traditional methods of pile removal, such as explosives or manual labor. With its advanced technology, it can significantly reduce the time and effort required for pile breaking tasks.

One of the key advantages of the hydraulic pile breaker is its precision. It can accurately target specific sections of a pile, minimizing damage to surrounding structures and ensuring a clean break. This precision is crucial in construction projects where accuracy and safety are of utmost importance.

Another benefit is its versatility. The hydraulic pile breaker can be used on various types of piles, including round, square, and rectangular piles. It is suitable for different construction sites, ranging from small-scale projects to large infrastructure developments.

In addition to its efficiency and versatility, the hydraulic pile breaker is also environmentally friendly. It produces less noise and dust compared to traditional methods, reducing the impact on the surrounding environment and nearby communities.

The applications of hydraulic pile breakers are widespread. They are commonly used in the construction of bridges, buildings, and other infrastructure projects. They can also be employed in the demolition of old structures where piles need to be removed.

In conclusion, the hydraulic pile breaker is a valuable tool in the construction industry. Its efficiency, precision, versatility, and environmental friendliness make it an ideal choice for pile breaking tasks. Whether it’s a large-scale construction project or a small renovation, the hydraulic pile breaker can help streamline the process and ensure a successful outcome.

Engineering Case

Main Product Configuration

Pile breaker parameter | ||||||||||||||||||||

Module quantity | pcs | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | |||||||

Total weight | KG | 1600 | 2624 | 2952 | 3280 | 3608 | 3936 | 4264 | 4592 | 4920 | 5248 | 5576 | 5904 | |||||||

Pile breaker diameter | mm | 200-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 460-1970 | 1620-2200 | 2200-2360 | 2360-2500 | |||||||

Applicable excavator tonnage | T | 20T-30T | 30T-40T |

| Hydraulic | |||||||||||||||

Maximum pressure applied to the drill rod | 300KN | Maximum pressure of a single oil cylinder | 20L/min | Tonnage of supporting construction machinery | ≥20t | |||||||||||||||

hydraulic oil cylinder max travel | 300mm | Drill rod diameter | 110mm | Single module weight | 328KG | |||||||||||||||

hydraulic oil cylinder max press | 30MPa | Single pile breaking height | ≤500mm | Single module size | 885*780*340mm | |||||||||||||||

Hydraulic station parameter | ||||||||||||||||||||

Motor power | 22KW | Poles No | 4 | Motor speed | 1470 rpm | Motor voltage | 3ph | Pump rated displacement | 107L/min | Normal operating pressure of the system | ||||||||||

Maximum operating pressure of the system | 30MPa | flow | 45L/MPa | Oil box capacity | 400L | Electromagnetic valve/control voltage | AC220V | weight | 480KG | 25 MPa | ||||||||||

Feature

Modular design, can be connected to various construction machinery, can add or reduce modules according to the size of the pile, convenient and fast

If the customer has an excavator, they can directly use the hydraulic power of the excavator and connect it directly without purchasing a hydraulic station!

If there is no excavator, a hydraulic station is required. Generally, it is recommended to use excavator power.