C6241/C6246/C6246E common lathe

C6241/C6246/C6246E common lathe

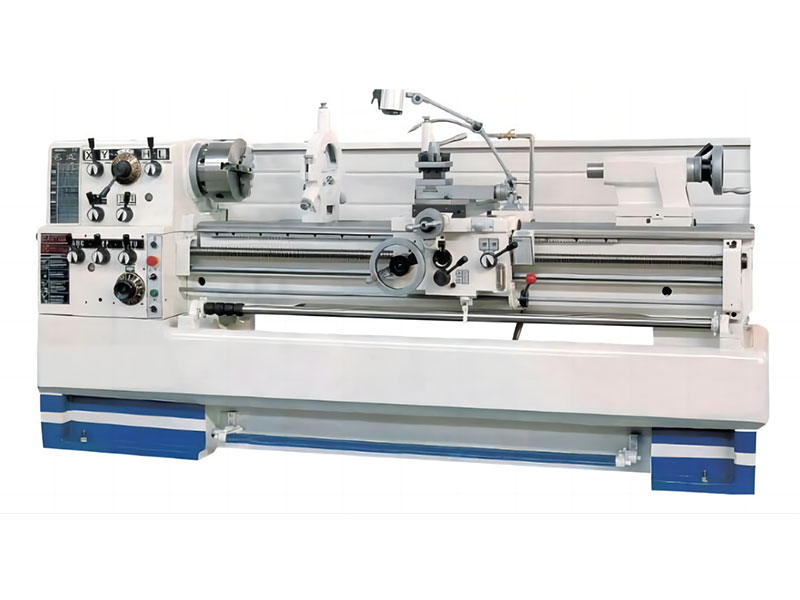

The C6241/C6246/C6246E common lathe stands as a cornerstone in the field of mechanical machining, renowned for its reliability and adaptability across diverse industrial sectors. As a classic series of horizontal common lathes, these models are widely utilized in small to medium-sized manufacturing workshops, repair facilities, and educational institutions, catering to both professional production and skill-training needs. Designed to handle a broad range of turning operations—including cylindrical turning, facing, threading, and grooving—they excel in processing various materials such as carbon steel, alloy steel, cast iron, and non-ferrous metals like aluminum and copper. Whether it’s producing precision components for automotive parts, crafting custom hardware for machinery, or performing maintenance on industrial equipment, the C6241/C6246/C6246E common lathe delivers consistent performance that meets the demands of modern machining workflows. Its user-friendly design and robust construction also make it a preferred choice for businesses seeking cost-effective solutions without compromising on quality, solidifying its position as a go-to tool for machining professionals worldwide

C6241/C6246/C6246E common lathe feature

The C6241/C6246/C6246E common lathe series is distinguished by a set of features that enhance efficiency, precision, and durability—key factors for optimizing machining productivity.

First, their heavy-duty bed structure, typically made of high-quality cast iron with rigorous heat treatment, ensures exceptional stability and vibration resistance during high-speed operation, minimizing deformation and guaranteeing consistent machining accuracy.

Second, the spindle system of these lathes is engineered for high rotational precision and torque: equipped with high-grade bearings, the spindle can maintain smooth rotation even under heavy loads, enabling precise cutting of workpieces with diameters ranging from small shafts to larger cylindrical parts.

Additionally, the feed mechanism offers multiple speed options for both longitudinal and cross feeds, allowing operators to adjust cutting parameters easily to match different material properties and machining requirements—whether achieving fine surface finishes for precision components or rapid material removal for roughing operations.

The C6246E model, as an upgraded variant, often includes enhanced features such as an improved lubrication system for extended component life, a more intuitive control panel for simplified operation, and compatibility with optional accessories like steady rests or follow rests, further expanding its versatility for complex machining tasks. Together, these features make the C6241/C6246/C6246E common lathe a valuable asset for businesses aiming to balance performance, flexibility, and cost-efficiency in their machining operations.

conventional lathe model and parameter

SPECIFICATION | MODELS | |||

C6241 1000, 1500,2000,300 0 | C6246 1000, 1500,2000,3000 | C6246E( BIG HOLE 1000, 1500,2000,3000 | ||

CAPACITY | ||||

Swing over red | 410mm( 16″) | 460mm( 18″) | 460mm( 18″) | |

Swing Over cross slide | 220mm(8- 13/ 16″) | 270mm( 10-3/4″) | 270mm( 10-3/4″) | |

Swing of gap | 640mm(25- 1/8″) | 690mm(27- 1/8″) | 690mm(27- 1/8″) | |

Length of gap | 165mm(6- 1/2″) | |||

Width of bed | 300mm( 11- 13/ 16″) | |||

HEADSTOCK | ||||

Spindle nose | D1-6 | |||

Spindle bore | 58mm(2- 1/4″) | 80mm(3- 1/8”) | ||

Taper of spindle bore | No.6Morse | No.7Morse | ||

Range of spindle speed | 12 changes, 25~2000r/min | |||

FEEDS AND THREADS | ||||

Max.travel of compound rest | 128mm(5″) | |||

Max.travel of cross slide | 285mm( 11- 1/4″) | |||

Leadscrew pitch | 6mmOr4T.P.I | |||

Max.section of tool | 25×25mm( 1 × 1″) | |||

Longitudinal feeds range | 42 kinds, 0.031~1.7mm/rev(0.0011″~0.0633″/rev) | |||

Cross feeds range | 42 kinds, 0.014~0.784mm/rev(0.00033″~0.01837″/rev) | |||

Metric threads range | 41 kinds, 0. 1~14mm | |||

Inch threads range | 60kinds2- 112T.P.I | |||

Diametrical pitches range | 50kinds4- 112D.P. | |||

Module pitches range | 34kinds0.1-7M.P. | |||

TALLSTOCK | ||||

Dia of tailstock sieeve | 60mm(2-5/ 16″) | |||

Travel of tailstock sleeve | 128mm(5″) | |||

Morse taper of tailstock sleeve | No.4Morse | |

MOTOR | ||

Power of main motor | 5.5kW(7.5HP) 3PH | |

Power of coolant pump | 0.1kW( 1/8HP) 3PH | |

DIMENSION AND WEIGHT | ||

Overall dimension(L ×W ×H)mm | 2200x1080x1340mm( 1m) 2750x1080x1340mm ( 1.5m) 3250x1080x1340mm (2m) | 2200x1080x1370mm ( 1m) 2750x1080x1370mm ( 1.5m) 3250x1080x1370mm (2m) |

Packing size(L ×W ×H)mm | 2250x1120x1620mm( 1m) 2800x1120x1620mm ( 1.5m) 3300x1120x1620mm (2m) | 2250x1120x1650mm( 1m) 2800x1120x1650mm ( 1.5m) 3300x1120x1650mm (2m) |

Net weight | 1580KG( 1m) 1745kg( 1.5m) 1900kg(2m) | 1645kg( 1m) 1810kg( 1.5m) 1965kg(2m) |

Gross weight | 1844kg( 1m) 2049kg( 1.5m) 2229kg(2m) | 1910kg( 1m) 2115kg( 1.5m) 2295kg(2m) |

No | C6241 (Standard Accessories) | C6246(C6246E) (Standard Accessories) | Quantity |

1 | 3-jaws self centering chuck Φ250MM | 3-jaws self centering chuck Φ250MM | 1 Pcs |

2 | 4-jaws independent Φ300MM | 4-jaws independent Φ300MM | 1 Pcs |

3 | Foot brake | Foot brake | 1 Set |

5 | Face Plate | Face Plate | 1 Pcs |

6 | Auto lubrication system | Auto lubrication system | 1 Pcs |

7 | Full length splash guard | Full length splash guard | 1 Pcs |

8 | Operational Manual、toolbox | Operational Manual 、toolbox | 1 Pcs |