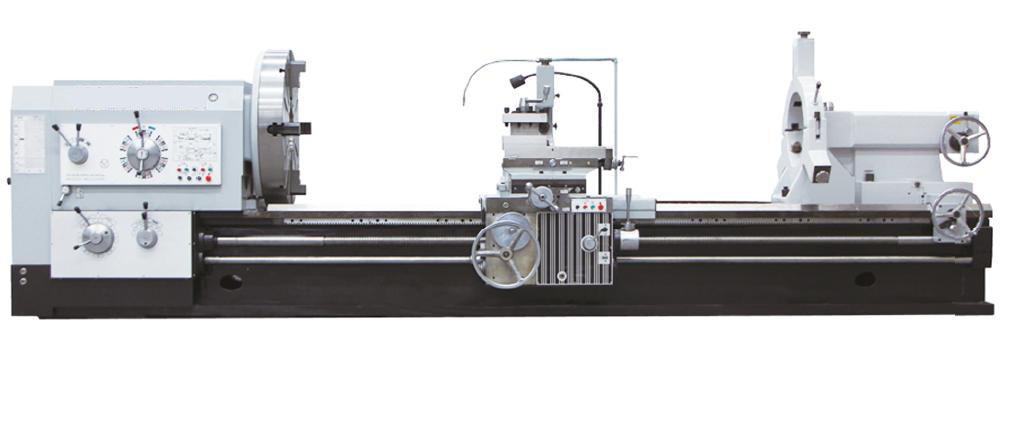

CW61-B Horizontal lathe

CW61-B Horizontal lathe

The CW61-B series horizontal lathe stands out as a reliable workhorse for metalworking industries, designed to deliver accuracy, durability, and versatility for both small-batch and large-volume production. Its robust construction—featuring a high-rigidity cast iron bed—minimizes vibration during high-speed operations, ensuring consistent machining quality for components like shafts, sleeves, and discs. Equipped with a powerful main motor, the CW61-B series offers adjustable spindle speeds to handle a wide range of materials, from soft aluminum to hard steel. The advanced feed mechanism supports precise thread cutting (metric, imperial, and modular) and smooth longitudinal/transverse feeding, reducing manual adjustments and boosting efficiency. User-friendliness is another core advantage. The lathe’s intuitive control panel simplifies speed and feed setting, while its ergonomic design—including a comfortable handwheel and clear scale markings—lowers operator fatigue during long shifts. Additionally, the CW61-B series is easy to maintain, with accessible components that reduce downtime for routine checks or repairs. Ideal for workshops, factories, and vocational training centers, the CW61-B horizontal lathe balances performance and cost-effectiveness, making it a top choice for businesses seeking to enhance machining productivity without compromising on precision. Would you like me to expand this into a longer **CW61-B series horizontal lathe product specification sheet** with technical parameters like spindle bore size and maximum turning diameter?

CW611-B horizontal lathe Parameter

SPECIFICATION | UNIT | CW61100B | CW61125B | CW61140B | CW61160B | |

| Swing over bed | ii | 1000 | 1250 | 1400 | 1600 |

Swing over cross slide | mm | 610 | 850 | 1000 | 1200 | |

Capacity | Distance between centers | mm | 1500/3000-10000 | 1500/3000-10000 | 1500/3000-10000 | 1500/3000-10000 |

Guideway width | mm | 755 | 755 | 755 | 755 | |

Max.load capacity |

| 6 | 6 | 6 | 6 | |

Spindle | Spindle bore | mm | 130 | 130 | 130 | 130 |

Spindle bore taper |

| Metrio φ140/MT6 | Metrio φ140/MT6 | Metro φ140/MT6 | Metrio φ140/MT6 | |

Spindle rose type |

| A2-15 | A2-15 | A2-15 | A2-15 | |

Spindle speed steps |

| FWD.21 steps | FWD.21 steps | FWD.21 steps | FWD.21 steps | |

Spindle speed range | rpm | 3.15-315 | 3.15-315 | 3.15-315 | 3.15-315 | |

Chuck | mm | φ1000 4-jaw manual | ||||

Turret | Turrettool post | – | Manual turret 4 position | |||

Tool shank size | mm | 45×45 | 45×45 | 45×45 | 45×45 | |

Feed | Xaxis travel | mm | 520 | 620 | 620 | 620 |

Zaxis travel | mm | 1250/2750-9750 | 1250/2750-9750 | 1250/2750-9750 | 1250/2750-9750 | |

Xaxis feed grade/range | mm/r | 56kinds/0.05-6 | 56kinds/0.05-6 | 56kinds/0.05-6 | 56kinds/0.05-6 | |

Zaxis feed grade/range | mm/r | 56kinds/0.1-12 | 56kinds/0.1-12 | 56kinds/0.1-12 | 56kinds/0.1-12 | |

Xaxis rapid feed speed | mm/min | 1870 | 870 | 1870 | 1870 | |

Zaxis rapid feed speed | mm/min | 3740 | 3740 | 3740 | 3740 | |

Metric thread grace/range | mm | 44kinds/1-120 | 44kinds/1-120 | 44kinds/1-120 | 44kinds/1-120 | |

Inch thread grade/range | T.P.I | 31kinds/28-38 | 31kinds/28-38 | 31kinds/28-38 | 31kinds/28-3/8 | |

Module thread grade/range | mm | – | – | – | – | |

DP thread Grade/range | DP. | – | – | – | – | |

Tailstock | Tailstock quill diameter | mm | φ160 | φ160 | φ160 | φ160 |

Tailstock quill aper |

| MT6 | MT6 | MT6 | MT6 | |

Tailstock quilltravel | mm | 300 | 300 | 300 | 300 | |

Motor | Main spindle motor | kW | 22 | 22 | 22 | 22 |

Rapid traverse motor | kW | 1.5 | 1.5 | 1.5 | 1.5 | |

Coolant pump motor | KW | 0.125 | 0.125 | 0.125 | 0.125 | |

mcnsion | WidthxHeight | mm | 2000×1800 | 2000×1950 | 2250×2050 | 2250×2150 |

Length | mm | 4600/6100 | 4600/6100 | 4600/6100 | 4600/6100 | |

3m | Net weight |

| 9.6/10.7 | 10.6/11.7 | 11.2/12.3 | 13.1/14.0 |