Solid Carbide deep hole Guide Pads

Solid carbide deep hole Guide Pads for deep hole drilling head

Solid carbide deep hole Guide Pads are key components of deep hole drill head.

It plays a crucial role in the processing of deep hole drilling processing and is also a frequently replaced vulnerable part in drills. Because in the process of deep hole machining, it plays a role in supporting the drill bit and guiding. If the pads is worn, it will have an impact on the accuracy of deep hole machining. Therefore, we need to check the wear of the blades and guide pads on the drill bit before processing.

Once wear is found, it should be replaced immediately, which is necessary to obtain good aperture accuracy.

deep hole drilling Guide pads Display

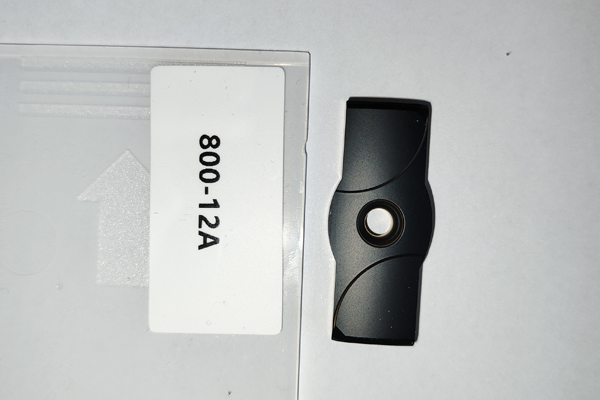

At present, we supply 800 series solid carbide deep hole Guide Pads, with typical models including 800-06A, 800-07A, 800-08A, 800-10A, 800-12A, etc.

At the same time, we also supply GPS series , typical models include GPS-06-2075, GPS-06-2085, GPS-06-20-100, GPS-06-20-120, GPS-07-20-120, GPS-08-25-155, GPS-10-30-200, GPS-10-35-200, GPS-12-35-250, GPS-14-40-250, and so on.

There are also WP08, WP10, WP12, WP14, etc

GC18, GC14, GC12, etc

Specifications table

|

Dimensions(mm) |

|||||

Inserts Shape |

Type |

Diameter range |

IN |

W1 |

T |

RE |

|

GPS-04-16-055 |

14.00-15.99 |

16.0 |

4.00 |

2.00 |

5.50 |

GPS-05-18-060 |

14.00-15.99 |

18.0 |

5.00 |

2.50 |

6.00 |

|

GPS-06-20-075 |

16.00-18.00 |

20.0 |

6.00 |

3.00 |

7.50 |

|

GPS-06-20-085 |

18.01-21.00 |

20.0 |

6.00 |

3.00 |

8.50 |

|

GPS-06-20-100 |

21.01-28.00 |

20.0 |

6.00 |

3.00 |

10.0 |

|

GPS-06-20-120 |

25.01-28.00 |

20.0 |

6.00 |

3.00 |

12.0 |

|

GPS-07-20-120 |

30.00-39.00 |

20.0 |

7.00 |

3.50 |

12.0 |

|

GPS-08-25-155 |

39.01-45.00 |

25.0 |

8.00 |

4.50 |

15.5 |

|

GPS-10-30-200 |

45.01-57.00 |

30.0 |

10.0 |

4.50 |

20.0 |

|

GPS-10-35-200 |

45.01-57.00 |

35.0 |

10.0 |

6.00 |

20.0 |

|

GPS-12-35-250 |

57.01-65.00 |

35.0 |

12.0 |

5.50 |

25.0 |

|

GPS-14-40-250 |

57.01-65.00 |

40.0 |

14.0 |

7.50 |

25.0 |

|

GPS14+1 |

57.01-65.00 |

40.0 |

14.0 |

8 |

25.0 |

|

GPS14+2 |

57.01-65.00 |

40.0 |

14.0 |

8.5 |

25.0 |

|

GPS14+3 |

57.01-65.00 |

40.0 |

14.0 |

9 |

25.0 |

|

GPS-18-40-300 |

57.01-65.00 |

40.0 |

18.0 |

9.00 |

30.0 |

|

GPS18+1 |

57.01-65.00 |

40.0 |

18.0 |

9.5 |

30.0 |

|

GPS18+2 |

57.01-65.00 |

40.0 |

18.0 |

10 |

30.0 |

|

GPS18+3 |

57.01-65.00 |

40.0 |

18.0 |

10.5 |

30.0 |

|

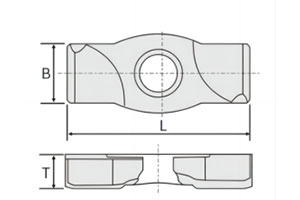

INSERT MODEL

|

Dimensions(mm) |

||||

Inserts Shape |

Type |

Diameter range |

L |

B |

T |

|

800-06A |

25.00-31.00 |

18 |

6 |

3.0 |

800-07A |

31.01-39.60 |

20 |

7 |

3.5 |

|

800-08A |

39.61-47.00 |

25 |

8 |

4.5 |

|

800-10A |

47.01-54.99 |

30 |

10 |

4.5 |

|

800-12A |

55.00-65.00 |

35 |

12 |

5.5 |

|

The feature of deep hole guide pads

The Features of Deep Hole Guide Pads

In the realm of precision machining, especially in deep hole drilling operations, deep hole guide pads play a crucial role. These unassuming components are vital for ensuring the accuracy, efficiency, and overall quality of the drilling process.

Exceptional Wear Resistance

Deep hole guide pads are engineered to withstand the intense friction generated during deep hole drilling. They are often made from high – grade materials such as carbide or high – strength alloys. These materials have an inherent ability to resist wear, allowing the guide pads to maintain their shape and functionality over extended periods of use.