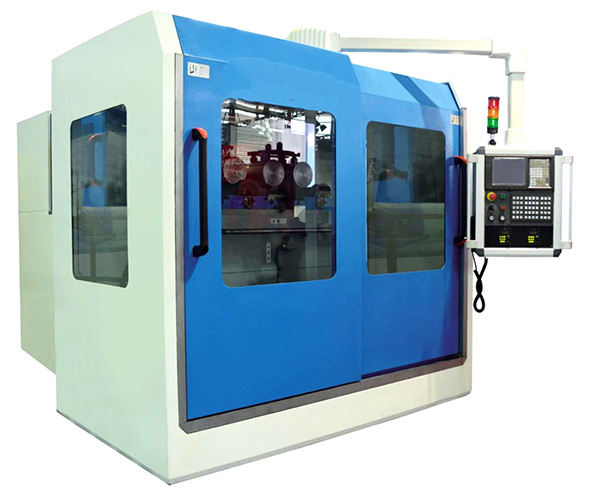

Deep Hole Gundrill Machine

Single Axis CNC Deep Hole Gun Drilling Machine& 3 coordinate deep hole gun drill machine

Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

The machine tool equip the headstock, so the workpiece rotate and cutting tool rotate and feed at the same time, and the accuracy is very high.

if need more Deep Hole Gundrill Machine infomation,please contact us.

Types of CNC Deep Hole Gun Drilling Machine

Three Coordinates CNC Deep Hole Gun Drilling Machine

Single Coordinate CNC Deep Hole Gun Drilling Machine

Product Description

Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

The machine tool equip the headstock, so the workpiece rotate and cutting tool rotate and feed at the same time, and the accuracy is very high.

Machine features:

Bed body and the box body is made of high quality cast iron casting, with good rigidity and stability.

It doesn’t need to return cutting tool in the process of drilling deep hole.

It adopts CNC control system, a high degree of automation.

Feed movement is driven by AC servo motor, and is driven by ball screw pair, and it is stepless speed regulation.

It adopts sliding guide rail, moving parts bottom with special material, low speed running smoothly, without crawling.

The drilling bar box is stepless speed regulation.

The bearing of spindle and guideway adopt automatic intermittent lubrication, etc.

High pressure cooling system adopts that frequency conversion motor drive gear pump, and the immersion cooler can control the oil temperature.

It adopts automatic chip removal machine.

It adopts all closed protective cover, and it is convenient to observe and good appearance.

With multiple automatic monitoring device.

Optional machining method:

A、standard configuration:

Workpiece rotate, cutting tool rotate and feed with gun drilling method.

B、optional method, the workpiece fixed, the cutting tool rotating and feed with gun drilling method.

Standard configuration:

Standard KND or GSK980T numerical control system, headstock, flat screen filter, hand pulse control box, drill pipe support, automatic chip removal machine, all protective cover, centralized lubricating oil station, cooling system, warning lights, adjusting tools, working light, tool pad iron, oil temperature controller, hydraulic system, etc.

Optional configuration:

Gun drill tools, auxiliary equipment, cutting oil, knife grinder, grinding device, jilt oil machine, drum filter machine, magnetic chip removal machine, electric box air conditioner, Siemens numerical control system, FANUC CNC system, hydraulic tailstock, clamp.