Vertical Honing Machine

CNC Vertical Honing Machine

ML0825 CNC vertical honing machine adopts hydraulic or servo expansion honing head, which can realize constant pressure, quantitative or double feed honing, and is easy to operate. This machine is suitable for honing and polishing of cylindrical deep-hole workpieces, such as various hydraulic cylinders, cylinders and valve bodies and other precision pipe fittings. The machining aperture accuracy can reach IT7 level or above, and the surface roughness can reach Ra0.2-0.4μm.

1.Machine Performance:

ML0825 CNC vertical honing machine adopts hydraulic or servo expansion honing head, which can realize constant pressure, quantitative or double feed honing, and is easy to operate. The machine tool adopts the workpiece to be fixed, and the honing head rotates and reciprocates to realize the honing function. This machine is suitable for honing and polishing of cylindrical deep-hole workpieces, such as various hydraulic cylinders, cylinders and valve bodies and other precision pipe fittings. The machining aperture accuracy can reach IT7 level or above, and the surface roughness can reach Ra0.2-0.4μm. By using local honing, the taper, ovality and local aperture error of the workpiece can be corrected. For some cold drawn steel pipes, honing can be performed directly. This honing machine is an ideal equipment with high precision and high efficiency. This machine tool is controlled by PLC special system in the honing process, the commutation is stable, the speed adjustment is convenient, it is easy to ensure the accuracy of the aperture size and reduce the labor intensity.

During the honing process of this machine , the size of the honing head is controlled safely and stably to ensure the consistency of the hole size and improve the efficiency of the honing process. For general cylindrical deep hole parts, rough and fine honing is carried out after boring, so as to efficiently achieve the dimensional accuracy of the hole. The machining diameter of this machine is Ф25-Ф250mm. This machine has the advantages of convenient operation, high production efficiency and good economic benefits. It can not only meet the needs of mass production, but also be suitable for the needs of single-piece and small-batch processing, and is an ideal equipment for inner hole processing of precision parts.

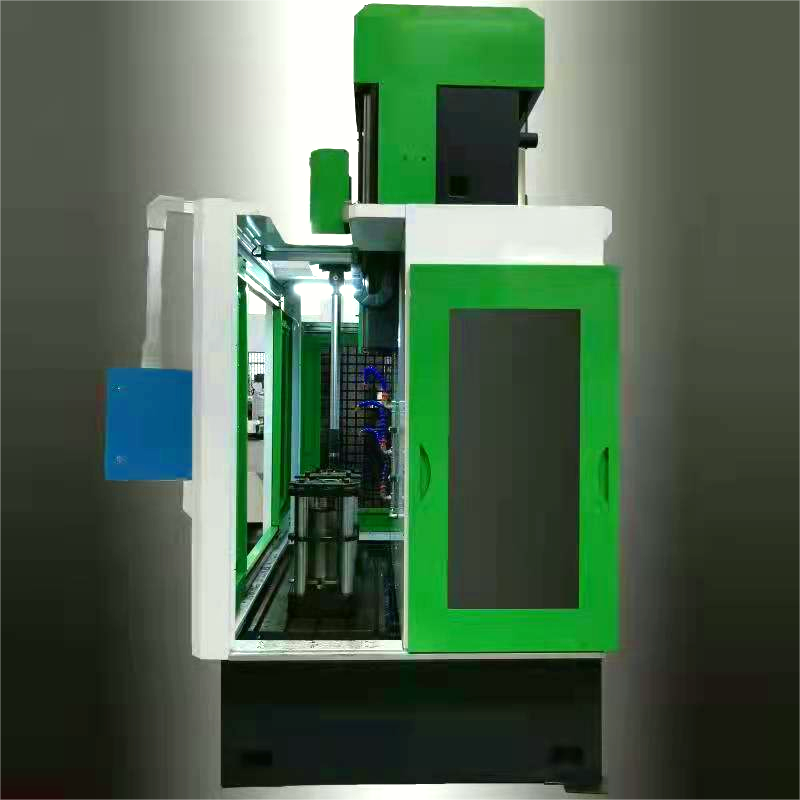

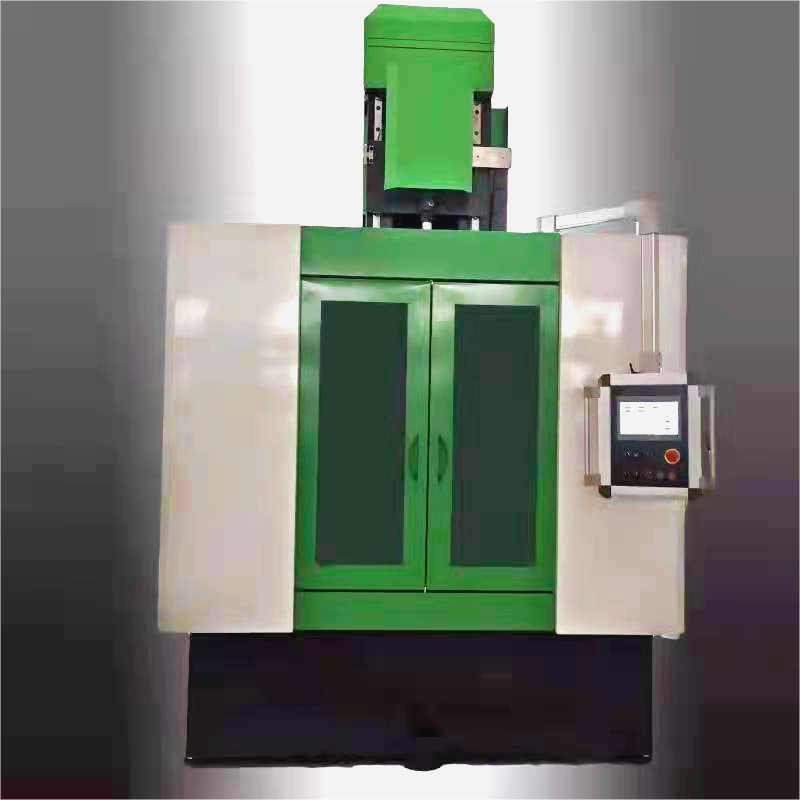

2.Product Display

3.Parameter Part

3.1 Diameter range of machining hole (inner diameter): φ 25 – φ 250mm; (The honing tool needs to be replaced)

3.2Workpiece clamping range: X1200-Y700-Z1200 (mm);

The hole in Y direction must be in the centering position at the maximum clamping range.

3.3 Maximum processing depth: ≥ 800mm;

3.4 Processing accuracy:

roundness ≤ 0.003-0.015m, dimension tolerance ≤ 0.03mm

Surface roughness ≤ 0.2um

3.5 Power of main motor of spindle box: 7.5KW (AC variable frequency motor);

3.6 Spindle speed of spindle box: 5~250r/min

(frequency conversion control, stepless speed regulation);

3.7 Spindle box reciprocating motor: 5.5KW (servo motor);

3.8 Reciprocating speed of spindle box: 1~25m/min (servo control, infinitely variable speed):

3.9 Feed expansion motor 750w (servo motor, the minimum unit of feed simulation is 0.001 mm);

3.10 The flow of cooling pump is 100L/min, and the motor power of cooling system is 250W;

3.11 The motor power of magnetic separator is 45w. Flow 100 l/min;

3.12 Bearing capacity of workbench: 2000Kg;

3.13 Overall dimensions of equipment: 2200 wide * 1650 deep * 3280 high (mm)

3.14. Machine tool weight is about 4.5T

4.Basic Composition of the Machine

4.1Honing bar box:

It adopts a closed box, and the 7.5kW frequency conversion motor drives the main shaft to rotate through the direct connection to drive the gear of the spindle box. The speed is step less, and the speed range is 5-250 r/min. The output torque of the main shaft is large, and the transmission is stable. A hydraulic cylinder or a servo motor is installed at the rear end of the main shaft to control the expansion and contraction of the tool. Through the axial movement of the driving mandrel, the radial expansion of the honing bar is driven by the inner conical mandrel of the honing head, so as to realize the adjustment of the size of the tool.

4.2 Carriage rapid moving system:

The carriage is installed on the linear guide rail, and the servo motor drives the ball screw through the reducer to drive the carriage to reciprocate. The reciprocating speed is 1-25 m/min, which meets the speed requirement of the machining aperture.

4.3 Cooling system:

The cooling system is filtered by a sedimentation-magnetic separator, and a paper belt filter can be added. The filtration precision is less than 30μm.

4.4 Workpiece clamping:

According to the actual conditions such as the shape of the parts, or according to the customer’s requirements, design automatic or manual fixtures, the fixtures are installed on the worktable with T-slots, and the parts to be processed for the first time need to be calibrated with the spindle center , the same part processing does not need to calibrate the alignment later.

4.5 Bed part:

The machine tool is composed of a machine tool base, a column, and a fully protective sheet metal cover of the machine tool. There are movable doors on both sides of the machine tool to facilitate the hoisting of large parts. The operation position protective door can be moved on both sides to facilitate various clamping and operations. Require.

4.6 Electrical part:

This machine tool adopts Siemens PLC control system in the honing process, which can realize automatic cycle control, the reciprocating speed is displayed on the panel, the reversing is stable, and the speed adjustment is convenient; at the same time, it can realize the size control of the honing head, so as to ensure the machining accuracy and size of the hole. consistency. The dimensional accuracy of the aperture is guaranteed and the labor intensity is reduced. There is a pressure regulating switch on the panel, which can easily adjust the honing pressure. The display screen can show the machine status such as spindle load, honing head position, honing time, and the shape of the machined hole at all times, and the parameter setting is quick and convenient.

Machine parts list

| No | Name | Unit | qty | Remark |

| 1 | bed | set | 1 | |

| 2 | protection cover | set | ||

| 2 | main spindle box | set | 1 | |

| 4 | Head-stock reciprocating system | set | 1 | |

| 5 | Cooling filter system | set | 1 | |

| 6 | Workpiece clamping device | set | 1 | |

| 7 | Filter chip removal system | set | 1 | |

| 8 | Electrical system | set | 1 | |

| 9 | Distribution Cabinet | set | 1 |

Main accessories

| No | Name | Model | Qty | Brand | Origin |

| 1 | Spindle bear | 1set | harbin | CN | |

| 2 | Main motor | 7.5kW Inverted | 1set | Famous in china | CN |

| 3 | Main motor inverter | 7.5KW | 1set | Denmark | Denmark |

| 4 | Reciprocating motor | 5.5kW Servo | 1set | Famous in china | CN |

| 5 | Hydraulic station | 1.5kW | 1set | Famous in china | CN |

| 6 | server Driver | 5.5KW | 1set | Famous in china | CN |

| 7 | Servo motor | 5.5KW | 1set | Famous in china | CN |

| 8 | Electric component | 1set | Schneider | Germany | |

| 9 | Guide rail | 1set | Taiwan | ||

| 10 | Control system | PLC | 1set | Siemens | Germany |

| 11 | Cable | 1set | Famous in china | CN |