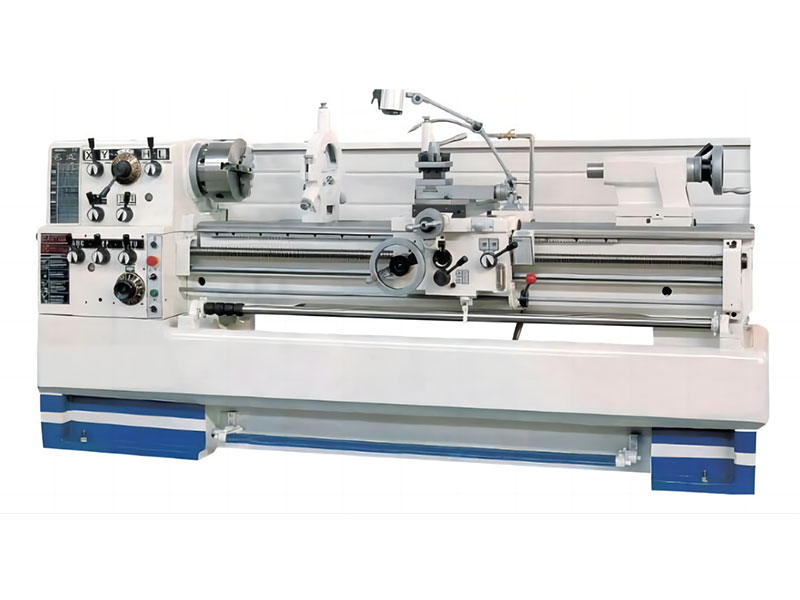

Conventional Lathe

Conventional Lathe

Our company sells conventional lathe of high quality, We have many foreign customer which can got us high quality products and services from remote.and you can enjoy our long term service.

These conventional lathes can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads. They are characteristics of power, high spindle speed, high rigidity. The various ferrous and non ferrous metals parts may be turned through the heavy cutting by carbon alloy tools.

The operation of a conventional lathe requires skill and expertise. The operator must have a good understanding of the machine’s controls and be able to make precise adjustments to achieve the desired results. This hands-on approach gives operators a sense of control and craftsmanship that is often lacking in automated machining processes.

welcome to inquiry our conventional lathe.

conventional lathe model and parameter

C0632A-TOP/36A-TOP

Standard configuration

1. Three jaw chuck 1 set

2. Center and center sleeve 1 set

3. Toolbox

MODELS | C0632A | C0636A |

Swing over bed | 330mm( 13″) | 360mm( 14″) |

Swing over cross slide | 198mm(7-25/32″) | 224mm(8- 13/ 16″) |

Swing over gap diameter | 476mm( 18-3/4″) | 502mm( 19-3/4″) |

Length of gap | 210mm(8- 1/4″) | 210mm(8- 1/4 “) |

Center heigh | 166mm(6- 1/2″) | 179mm(7″) |

Distance between center | 1000mm(40″) | 1000mm(40″) |

Bed width | 87mm(7-3/8″) | 187mm(7-3/8″ |

Bed length | 1655mm(65- 1/8”) | 1655mm(65- 1/8″) |

Bed height | 290mm( 11- 13/32″) | 290mm( 11- 13/32″) |

Spindle bore | 38mm( 1- 1/2″) | 38mm( 1- 1/2″) |

Spindle nose | D1-4 “ | D1-4″ |

Taper in nose | MT NO.5 | MT NO.5 |

Speeds number | 8 |

|

Range of spindle speed | 70-2000r/min | 70-2000r/min |

Cross slide width | 130mm(5-3/32″) | 130mm(5-3/32″) |

Cross slide travel | 170mm(6- 11/ 16″) | 170mm(6- 11/ 16″ |

Compound rest width | 80mm(3- 1/8″) | 80mm(3- 1/8″) |

Compound rest travel | 95mm(3-9/ 16″) | 95mm(3-9/ 16“) |

Lead screw diameter | 22mm(7/8″) | 22mm(7/8″) |

Lead screw thread | 8T.P.I.or 3mm | 8T.P.I.or 3mm |

Feed rod diameter | 19mm(3/4″) | 19mm(3/4″) |

Cuting tool max section | 16mm×16mm(5/8″×5/8″) | 6mm×16mm(5/8″×5/8″) |

Threads imperial pitches | 34 Nos.4-56 T P I | 34 Nos.4-56 T P I |

Threads metric pitches | 26 Nos.0.4-7 M.P | 26 Nos.0.4-7 M.P |

Longitudinal feeds imperial | 32 Nos.0.002-0.548″/Rev | 32 Nos.0.002-0.548″/Rev |

Longitudinal feeds metric | 32 Nos.0.052-0.392mm/Rev | 32 Nos.0.052-0.392mm/Rev |

Cross feeds imperial | 32 Nos.0.007-0.0187“/Rev) | 32 Nos.0.007-0.0187”/Rev |

Cross feeds metric | 32 Nos.0.014-0.380mm/Rev | 32 Nos.0.014-0.380mm/Res |

Quill diameter | 32mm( 1- 1/4″) | 32mm( 1- 1/4″) |

Quill travel | 100mm(3- 15/ 16″) | 100mm(3- 15/ 16″) |

Quill taper | MT NO.3 | MT NO.3 |

Main motor | 1.5kW(2HP) | 1.5kW(2HP |

Motor frequency | 50hz,60hz | 50hz,60hz |

Over dimension | 160x73x127CM | 160x73x127CM |

NET WEIGHT | 460KG | 460KG |

PACKING SIZE | 168X75X142CM | 168X75X142CM |

CM6241 conventional lathe

CM6241-1000MM/1500MM

(UNIVERSAL HORIZONTAL LATHE)

Standard Configuration

COMMODITY AND SPECIFICATION

3-jaws self centering chuck 250mm

4-jaws independent 350mm

Foot brake

Face Plate

Drive plate

Full length splash guard ,

chuck guard,

knife guard,

work light

Operational Manual,

dead center

Tool with machine1

Specification | Model |

CM6241 | |

×1000,1500 | |

Capacity |

|

Swing over bed | 410mm |

Swing over cross slide | 255 |

Swing in gap | 580mm |

Distance between centers | 1000mm |

Valid length of gap | 190mm |

Width of bed | 250 |

Headstock |

|

Spindle nose | D1-6 |

Spindle bore | 52mm |

Taper of spindle bore | No.6 Morse |

Range of spindle speed | 16 changes, 45~1800r/min |

Feeds and threads |

|

Compound rest travel | 140mm |

Max.travel of cross | 210mm |

slide |

|

Max.section of tool | 20×20mm |

Pitch thread of leadscrew | 4T.P.I. | |

Longitudinal feeds range | 0.05~1.7mm /rev | |

Cross feeds range | 0.025-0.85mm | |

Metric threads range | 39kinds, 0.2~14mm | |

Inch threads range | 45 kinds, 2~72T.P.I. | |

Diametrical pitches range | 21 kinds, 8~44DP | |

Module pitches range | 18kinds 0.3~3.5MP | |

Tailstock | ||

Dia. of tailstock sleeve | 50mm | |

Travel of tailstock sleeve | 120mm | |

Taper of tailstock sleeve | No.4 Morse | |

Motor | ||

Power of main motor | 2.2kw | |

Power of coolant pump | 0.1kW | |

Dimension and weight | |

Overall dimension |

|

(L ×W ×H) cm | 194x85x132cm |

Packing size(L ×W ×H) cm | 206x90x164cm |

Net weight | 1160kg |

Gross weight | 1350kg |

C6241 -C6246-C6246E conventional lathe

C6241/C6246/C6246E

SIMPLE INTRODUCTION

C62 series is horizontal lathe used for machining various kinds of steel parts. It is specially suitable for mass production of machining inside and outside cylinder surface,

end surface, metric and inch thread etc.

Note: C6246E is 105mm spindle big hole

SPECIFICATION | MODELS | |||

C624 1000, 1500,2000,300 0 | C6246E 1000, 1500,2000,3000 | C6246E( BIG HOLE 1000, 1500,2000,3000 | ||

CAPACITY | ||||

Swing over red | 410mm( 16″) | 460mm( 18″) | 460mm( 18″) | |

Swing Over cross slide | 220mm(8- 13/ 16″) | 270mm( 10-3/4″) | 270mm( 10-3/4″) | |

Swing of gap | 640mm(25- 1/8″) | 690mm(27- 1/8″) | 690mm(27- 1/8″) | |

Length of gap | 165mm(6- 1/2″) | |||

Width of bed | 300mm( 11- 13/ 16″) | |||

HEADSTOCK | ||||

Spindle nose | D1-6 | |||

Spindle bore | 58mm(2- 1/4″) | 80mm(3- 1/8”) | ||

Taper of spindle bore | No.6Morse | No.7Morse | ||

Range of spindle speed | 12 changes, 25~2000r/min | |||

FEEDS AND THREADS | ||||

Max.travel of compound rest | 128mm(5″) | |||

Max.travel of cross slide | 285mm( 11- 1/4″) | |||

Leadscrew pitch | 6mmOr4T.P.I | |||

Max.section of tool | 25×25mm( 1 × 1″) | |||

Longitudinal feeds range | 42 kinds, 0.031~1.7mm/rev(0.0011″~0.0633″/rev) | |||

Cross feeds range | 42 kinds, 0.014~0.784mm/rev(0.00033″~0.01837″/rev) | |||

Metric threads range | 41 kinds, 0. 1~14mm | |||

Inch threads range | 60kinds2- 112T.P.I | |||

Diametrical pitches range | 50kinds4- 112D.P. | |||

Module pitches range | 34kinds0.1-7M.P. | |||

TALLSTOCK | ||||

Dia of tailstock sieeve | 60mm(2-5/ 16″) | |||

Travel of tailstock sleeve | 128mm(5″) | |||

Morse taper of tailstock sleeve | No.4Morse | |

MOTOR | ||

Power of main motor | 5.5kW(7.5HP) 3PH | |

Power of coolant pump | 0.1kW( 1/8HP) 3PH | |

DIMENSION AND WEIGHT | ||

Overall dimension(L ×W ×H)mm | 2200x1080x1340mm( 1m) 2750x1080x1340mm ( 1.5m) 3250x1080x1340mm (2m) | 2200x1080x1370mm ( 1m) 2750x1080x1370mm ( 1.5m) 3250x1080x1370mm (2m) |

Packing size(L ×W ×H)mm | 2250x1120x1620mm( 1m) 2800x1120x1620mm ( 1.5m) 3300x1120x1620mm (2m) | 2250x1120x1650mm( 1m) 2800x1120x1650mm ( 1.5m) 3300x1120x1650mm (2m) |

Net weight | 1580KG( 1m) 1745kg( 1.5m) 1900kg(2m) | 1645kg( 1m) 1810kg( 1.5m) 1965kg(2m) |

Gross weight | 1844kg( 1m) 2049kg( 1.5m) 2229kg(2m) | 1910kg( 1m) 2115kg( 1.5m) 2295kg(2m) |

No | C6241 (Standard Accessories) | C6246(C6246E) (Standard Accessories) | Quantity |

1 | 3-jaws self centering chuck Φ250MM | 3-jaws self centering chuck Φ250MM | 1 Pcs |

2 | 4-jaws independent Φ300MM | 4-jaws independent Φ300MM | 1 Pcs |

3 | Foot brake | Foot brake | 1 Set |

5 | Face Plate | Face Plate | 1 Pcs |

6 | Auto lubrication system | Auto lubrication system | 1 Pcs |

7 | Full length splash guard | Full length splash guard | 1 Pcs |

8 | Operational Manual、toolbox | Operational Manual 、toolbox | 1 Pcs |

C6251-C6256-C6256E

C6251/C6256/C6256E

SIMPLE INTRODUCTION

C62 series is horizontal lathe used for machining various kinds of steel parts. It is specially suitable for mass production of machining inside and outside cylinder surface,

end surface, metric and inch thread etc.

Note: C6256E is 105mm spindle big hole

SPECIFICATION | MODELS | ||

C6251 1000, 1500,2000,300 0 | C6256E 1000, 1500,2000,3000 | C6256E( BIG HOLE 1000, 1500,2000,3000 | |

| CAPACITY | |||

| Swing over red | 510mm(20″) | 560mm(22″) | 560mm(22″) |

| Swing Over cross slide | 305mm( 12″) | 355mm( 14″) | 355mm( 14″) |

| Swing of gap | 735mm(28-7/8″) | 785mm(30-7/8″) | 785mm(30-7/8″) |

| Length of gap | 170mm(6- 11/ 16″) | ||

| Width of bed | 350mm( 13-3/4″) | ||

| HEADSTOCK | |||

| Spindle nose | D1-8 | ||

| Spindle bore | 80mm(3- 1/8″) | 105mm(4- 1/8”) | |

| Taper of spindle bore | No.7Morse | 113( 1:20) | |

| Range of spindle speed | 12changes25-2000r/min | 12changes 25- 1500r/min | |

| FEEDS AND THREADS | |||

Max.travel of compound rest | 130mm(5- 1/8″) | ||

| Max.travel of cross slide | 316mm( 12- 15/ 16″) | ||

| Leadscrew pitch | 6mmOr4T.P.L | ||

| Max.section of tool | 25×25mm( 1 × 1″) | ||

| Longitudinal feeds range | 35kinds0.059- 1.646mm/rev(0.0022″-0.0612″/rev) | ||

| Cross feeds range | 35kinds0.020-0.573mm(0.00048″-0.01354″) | ||

| Metric threads range | 47kinds0.2- 14mm | 41kinds 0.1- 14mm | |

| Inch threads range | 60kinds2- 112T.P.L | ||

| Diametrical pitches range | 50kinds4- 112D.P. | ||

| Module pitches range | 34kinds0.1-7M.P. | ||

TALLSTOCK | |||

| Dia of tailstock sieeve | 75mm(3″) | ||

Travel of tailstock sleeve | 180mm(7″) | |

Morse taper of tailstock sleeve | No.5Morse | |

MOTOR | ||

Power of main motor | 7.5kw( 10HP)3PH | |

Power of coolant pump | 0.1kw( 1/8HP),3PH | |

DIMENSION AND WEIGHT | ||

Overall dimension(L ×W ×H)mm | 2390x1150x1430mm( 1m) 2840x1150x1430mm( 1.5m) 3340x1150x1430mm(2m) 4340x1150x1430mm(3m) | 2390x1150x1460mm( 1m) 2840x1150x1460mm( 1.5m) 3340x1150x1460mm(2m) 4340x1150x1460mm(3m) |

Packing size(L ×W ×H)mm | 2450x1190x1740mm( 1m) 2900x1190x1740mm( 1.5m) 3400x1190x1740mm(2m) 4400x1190x1740mm(3m) | 2450x1190x1740mm( 1m) 2900x1190x1740mm( 1.5m) 3400x1190x1740mm(2m) 4400x1190x1740mm(3m) |

Net weight | 2070kg( 1m) 2160kg( 1.5m) 2435kg(2m) 2805kg(3m) | 2195kg( 1m) 2285kg( 1.5m) 2560kg(2m) 2930kg(3m) |

Gross weight | 2460kg( 1m) 2550kg( 1.5m) 2840kg(2m) 3270kg(3m) | 2600kg( 1m) 2690kg( 1.5m) 2980kg(2m) 3410kg(3m) |

No | C6251 (Standard Accessories) | C6256(C6256E) (Standard Accessories) | Quantity |

1 | 3-jaws self centering chuck Φ315MM | 3-jaws self centering chuck Φ315MM | 1 Pcs |

2 | 4-jaws independent Φ350MM | 4-jaws independent Φ350MM | 1 Pcs |

3 | Foot brake | Foot brake | 1 Set |

5 | Face Plate | Face Plate | 1 Pcs |

6 | Auto lubrication system | Auto lubrication system | 1 Pcs |

7 | Full length splash guard | Full length splash guard | 1 Pcs |

8 | Operational Manual、toolbox | Operational Manual 、toolbox | 1 Pcs |

C6266-C6280 conventional lathe

C6266A C6280

UNIVERSAL HORIZONTAL Lathe Machine

SIMPLE INTRODUCTION

C62 series is horizontal lathe used for machining various kinds of steel parts. It is specially suitable for mass production of machining inside and outside cylinder surface,

end surface, metric and inch thread etc.

MACHINE TOOL TYPE | C6266(A) | CQ6280 |

|

CAPACITY | |||

Swing Over Slide | Φ660mm | Φ800mm | |

Swing Over Cross Bed | Φ440mm | Φ570mm | |

Swing in Gap | Φ900mm | Φ1035mm | |

Length of Gap | 250mm | ||

Center Height | 330mm | 400mm | |

Distance Between Centers | 1500mm/2000mm/3000mm | ||

Width of Bed | 400mm | 400mm | |

Max. Section of Tool | 25mm × 25mm | ||

Max. Travel of Cross Slide | 368mm | 420mm | |

Max. Travel of Compound Rest | 230mm | 230MM | |

HEADSTOCK | |||

Spindle Bore | Φ105mm | ||

Spindle Nose | D1-8 | ||

Taper of Spindle Bore | Φ113mm( 1:20)/MT5 | ||

Spindle Speed Step | 16 | ||

Range of Spindle Speed | 25~1600rpm | 25~1600rpm | |

FEEDS AND THREADS | |||

Leadscrew Pitch | Φ40mm×2T.P.I. or Φ40mm×12mm | ||

Inch Threads Range | 7/ 16~80T.P.I. (54 kinds) | ||

Metric Threads Range | 0.45~120mm (54 kinds) | ||

MACHINE TOOL TYPE | C6266(A) | CQ6280 |

|

CAPACITY | |||

Swing Over Slide | Φ660mm | Φ800mm | |

Swing Over Cross Bed | Φ440mm | Φ570mm | |

Swing in Gap | Φ900mm | Φ1035mm | |

Length of Gap | 250mm | ||

Center Height | 330mm | 400mm | |

Distance Between Centers | 1500mm/2000mm/3000mm | ||

Width of Bed | 400mm | 400mm | |

Max. Section of Tool | 25mm × 25mm | ||

Max. Travel of Cross Slide | 368mm | 420mm | |

Max. Travel of Compound Rest | 230mm | 230MM | |

HEADSTOCK | |||

Spindle Bore | Φ105mm | ||

Spindle Nose | D1-8 | ||

Taper of Spindle Bore | Φ113mm( 1:20)/MT5 | ||

Spindle Speed Step | 16 | ||

Range of Spindle Speed | 25~1600rpm | 25~1600rpm | |

FEEDS AND THREADS | |||

Leadscrew Pitch | Φ40mm×2T.P.I. or Φ40mm×12mm | ||

Inch Threads Range | 7/ 16~80T.P.I. (54 kinds) | ||

Metric Threads Range | 0.45~120mm (54 kinds) | ||

No | Item (Standard Accessories) | Quantity |

1 | 3-jaws self centering chuck | 1 Pcs |

2 | 4-jaws independent | 1 Pcs |

3 | Foot brake | 1 Set |

4 | Steady rest | 1 Pcs |

5 | Follow rest | 1 Pcs |

6 | Face Plate | 1 Pcs |

7 | Auto lubrication system | 1 Pcs |

8 | Full length splash guard | 1 Pcs |

9 | Operational Manual;dead center | 1 Pcs |