U drill

What is U drill?

Indexable drill or blade drill bit is called u drill, which is Sandvik’s name. Later, people called it u drill. U-drill, also known as shallow hole drill, fast drill, violent drill, etc. U-drill is actually an internally cooled drill bit that can be continuously drilled with good cutting arrangement, making the efficiency of U-drill drilling very high.

Product Display

Characteristics and advantages of U drill

First of all,the difference between U drill and ordinary drill is that U drill uses hard alloy blades and designs inner and outer edge blades.After the drill is worn,the blades can be replaced directly without regrinding.

U drill has better rigidity and can use a high feed rate. Moreover,the processing diameter of U drill is much larger than that of ordinary drill.The drilling range can reach D10mm~80mm,and the longest processing depth can reach 5 times diameter.

The precision of the u-drill is higher than that of the conventional drill,and the finish is better, and the U-drill can correct the precision of the hole position.

U drill can drill holes on surfaces with inclination angles less than 30~without reducing cutting parameters.

When the cutting parameters of U drill are reduced by 30%,discontinuous cutting can be realized, such as processing intersecting hole,intersecting hole and phase perforation.

U drill can realize drilling of multi-step holes,and can boring,chamfer and eccentric drilling.

The drilling cuttings of U drill are mostly short cuttings,and the internal cooling system can be used for rapid chip removal without iron cuttings,which is conducive to product processing continuity, shorten processing time and improve efficiency.

There is no need to Pre-drill the center hole with U drill,and the bottom surface of the processed

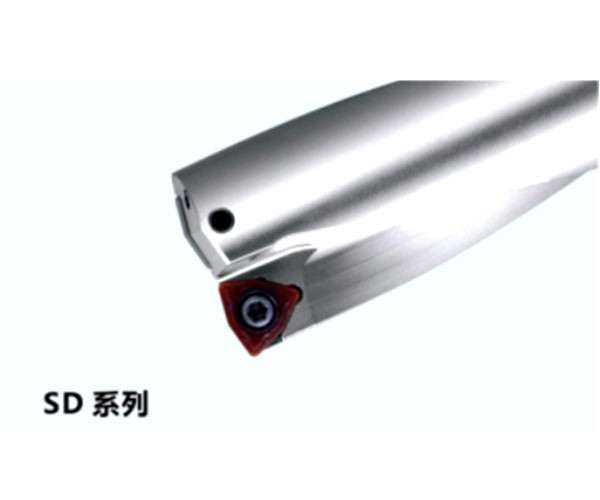

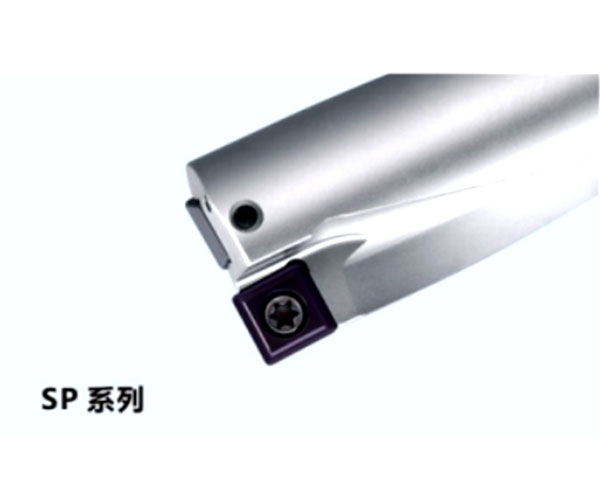

U drill type SD AND SP type

Model code rules

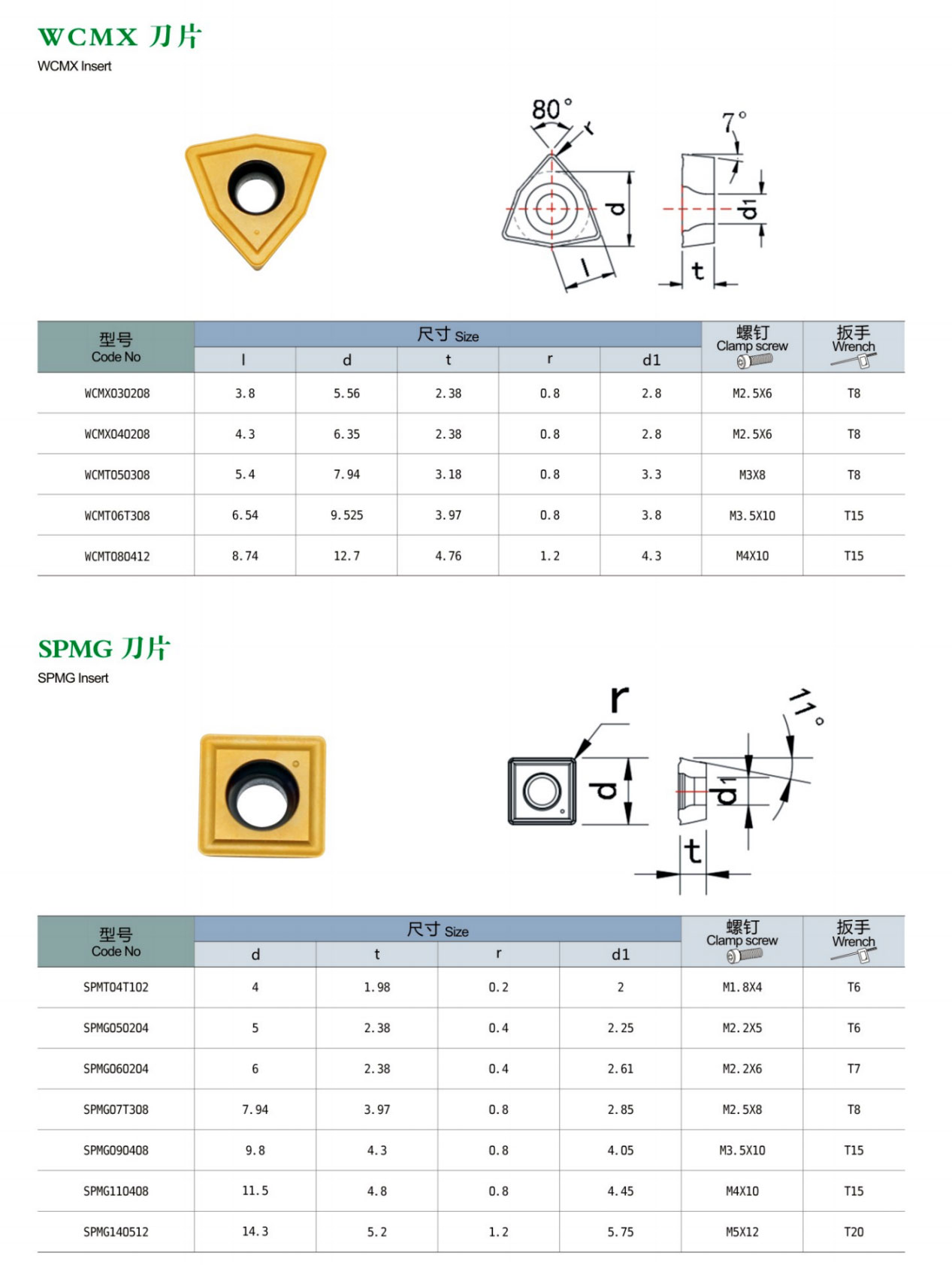

U drill insert type

Bit features

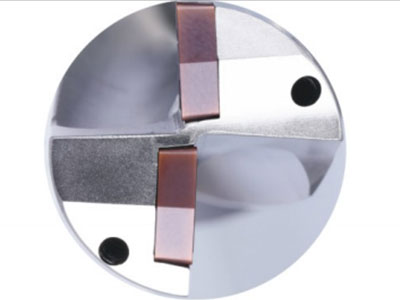

Chip removal tank

Innovative spiral groove design,inside and outside groove ratio 6:4, better chip removal.

The blade postion

Flat blade position, better fit with the blade, effectively improve the cutting effect

Tool rod rigid

The edge chanfer is smaller,improve the rigidity of the cutter bar,and embrace chip discharge effectively protects the cutter body from wear.

Oil cooling system

Increase oil cold water hole 1.5 times, better cooling,faster chip removal.

Cold connection forlathe oil

Handle tail with tube screw,easy to use lathe oil cold.

Excellent chip breaking control

Updated blade Angle,better cutting.