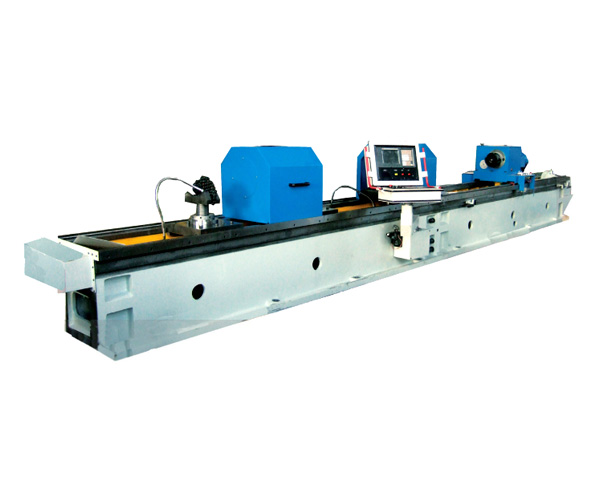

Deep Hole Honing Machine

Deep Hole Honing Machine

Deep Hole Honing Machine includes machine tool bed, headstock, feed unit, reciprocating transmission, fixture, honing oil cooling, honing rod, honing head, steel pipe clamping table, control system, etc.

This machine is match with KND,SIEMENS, FANUC CNC system.AC servo motor, honing box adopt stepless speed, Autocycle timing control unit is used on this machine during reciprocating honing so as to assure accuracy of machined holes and decrease the intensity of labour.

It can perform not only honing of mass products but also small batch workpieces. It is perfect equipment for machining deep hole parts.

Product Description

The usage of 2M2125A 2M2135A Deep Hole Honing Machine is a special equipment used for honing cylindrical deep hole parts such as various hydraulic oil cylinders and cylinders. Hole Diameter accuracy of machined workpieces can be up to or over IT7 and surface roughness Ra0.2-0.4μm. It can also repair and maintain taper and ellipticity of machined workpieces with the help of partial honing.

This machine is match with KND,SIEMENS, FANUC CNC system.AC servo motor, honing box adopt stepless speed, Autocycle timing control unit is used on this machine during reciprocating honing so as to assure accuracy of machined holes and decrease the intensity of labour.

Sand blades and workpieces always maintain constant pressure during honing. It is a feature of high efficiency and strong cutting force. It can perform rough and finished honing of general cylindrical deephole parts after rough- boring. It can directly perform high efficiency honing of cold drawing steel pipes. Traditional deep hole processing is simplified by using this machine.

Productivity is greatly increased. Materials of honed workpieces may be casting iron or all kinds of steel including quench parts. Cooling system of this machine adopts the method of three-step filtering in order to assure clearing of coolant.

This machine is controlled by electrical operating center. It is easy, safe and reliable in operation.

It can perform not only honing of mass products but also small batch workpieces. It is perfect equipment for machining deep hole parts

machine features:

1)The control program includes delayed pause honing at both ends, which can specify the honing of any section of the hole. The length and times of short stroke honing can be compiled at will, and the blind hole honing can be carried out.

2)It is easy to maintain, and the accessories are mainly standard parts;

3) Compact structure and minimum floor area.

4) Product standardization, long-term provision of accessories.

Machine performance:

SKH-A2030 deep hole honing machine adopts hydraulic expanding honing head, which can realize constant pressure honing and is easy to operate. The machine tool uses the workpiece fixed, the honing head rotates and moves back and forth to realize the honing function. The machine is suitable for honing and polishing cylindrical deep hole workpieces, such as various hydraulic cylinders, cylinders and other precision pipe fittings. The machining aperture accuracy can reach it7 or above, and the surface roughness can reach Ra0 2-0.4 μ m。 Using local honing, the taper, Ovality and local aperture errors of the machined parts can be corrected. For some cold drawn steel pipes, honing can be carried out directly. The honing machine is an ideal equipment with high precision and high efficiency. The machine tool is controlled by numerical control system in the honing process, with stable commutation, convenient speed regulation, easy to ensure the accuracy of aperture size and reduce labor intensity.

In the honing process, the machine tool can safely and stably control the honing head size, ensure the consistency of aperture size, and improve the efficiency of honing deep hole processing. For general cylindrical deep hole parts, rough and fine honing is carried out after rough boring. If cold drawn steel pipe is used, strong honing can be carried out directly, which changes the traditional process method of deep hole processing and effectively improves the productivity. The machining diameter range of this machine tool is Ф 40- Ф 300mm。 The machine tool has the advantages of convenient operation, high production efficiency and good economic benefits. It can not only adapt to mass production, but also meet the needs of single piece small batch processing. It is an ideal equipment for deep hole finishing.