Deep hole machining—defined by depth-to-diameter ratios (D/d) exceeding 10:1—poses unique challenges: maintaining accuracy, controlling chip buildup, and ensuring consistent surface finish. For manufacturers tackling these tasks, the indexable deep hole boring head has emerged as a game-changing solution, blending flexibility, durability, and efficiency to address diverse industrial needs.

Core Features of Indexable Deep Hole Boring Heads: Beyond Basic Machining

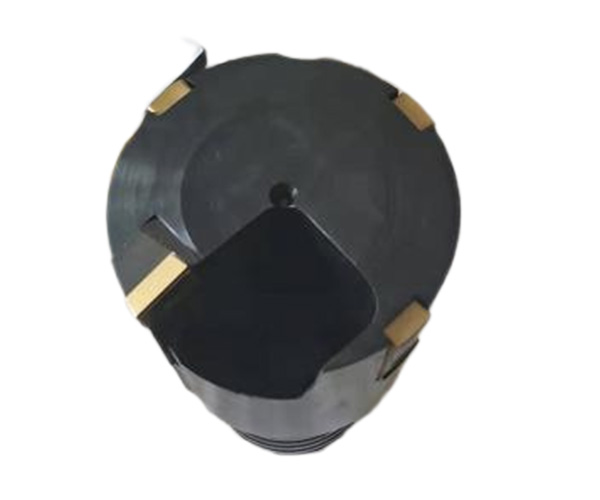

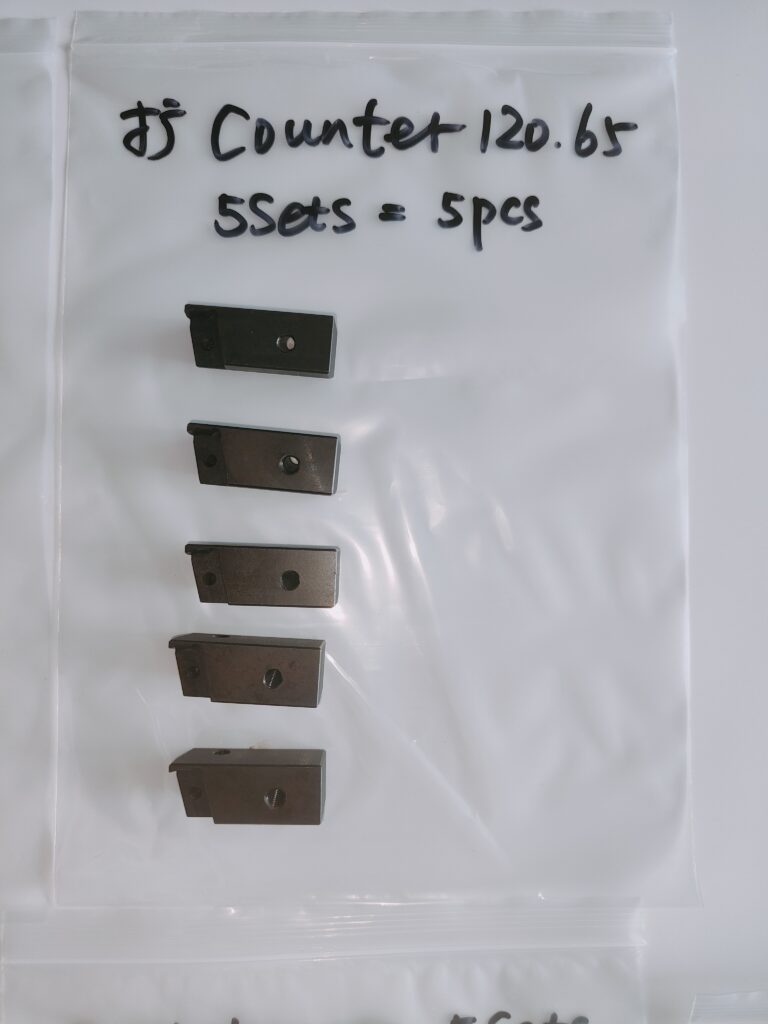

What sets this tool apart from traditional solid boring heads? Its defining feature is the indexable carbide inserts—replaceable cutting tips that eliminate the need for regrinding after wear. This not only reduces downtime (insert changes take seconds, not hours) but also ensures consistent precision: most models maintain hole tolerance within IT7-IT9, critical for applications where even 0.01mm deviation can compromise performance.

Additionally, indexable designs prioritize adaptability. Many heads support multiple insert grades, allowing manufacturers to switch between materials (e.g., coated carbide for stainless steel, cermet for aluminum) without replacing the entire tool. Rigid tool bodies, often made of high-strength alloy steel, minimize vibration during deep cuts— a common issue in long-reach machining that leads to poor surface quality. For deep hole tasks specifically, this stability translates to smoother inner walls, with surface roughness (Ra) typically ranging from 0.8 to 3.2 μm.

Deep Hole Applications: Solving the “Long-Reach” Problem

The indexable deep hole boring head excels in scenarios where standard tools struggle to reach or evacuate chips. A prime example is hydraulic cylinder manufacturing: cylinders for construction equipment or industrial presses often require holes 500mm deep (or more) with strict straightness. The tool’s internal chip evacuation system—paired with high-pressure coolant channels—flushes chips out through the tool’s center, preventing clogging that can scratch the hole wall or break the insert.

Another key application is engine block machining for automotive and heavy machinery. Crankshaft oil galleries, with D/d ratios up to 15:1, demand precise oil flow paths to reduce engine wear. Indexable heads here deliver uniform hole diameter across the entire depth, ensuring optimal oil circulation. Even in energy sector projects—such as drilling deep holes in wind turbine gearboxes—the tool’s rigidity handles the torque of cutting hard alloy steels, maintaining accuracy over extended machining cycles.

Cross-Industry Utility: From Aerospace to Medical Devices

While deep hole machining is its specialty, the indexable boring head’s versatility extends to other high-demand sectors. In aerospace manufacturing, it processes titanium alloy landing gear components and nickel-based superalloy engine casings. These materials require high-temperature resistance, so the tool’s heat-resistant inserts (e.g., ceramic-reinforced carbide) withstand cutting temperatures up to 1,200°C without degrading.

The medical industry relies on the tool for precision parts like orthopedic implant shafts and surgical instrument lumens. For example, femoral implants need smooth, deep holes for bone screws—holes that must be free of burrs to avoid tissue irritation. The indexable head’s clean cutting action and consistent finish meet these strict biocompatibility standards.

Even in mold and die making, the tool shines: it bores deep cooling channels in injection molds, ensuring uniform temperature distribution during plastic molding. This reduces part warpage and improves production yield—a critical factor for high-volume consumer goods manufacturing.

Internal Chip Evacuation: The Unsung Hero of Deep Hole Success

No discussion of indexable deep hole boring heads is complete without highlighting their internal chip evacuation system. Unlike external chip evacuation (where chips exit along the tool’s outer surface), internal evacuation uses a hollow tool shaft and high-pressure coolant to push chips out through the center. This design is a game-changer for deep holes:

It eliminates chip “packing” (a major cause of tool breakage in long-reach cuts).

Coolant reaches the cutting edge directly, reducing insert wear and extending tool life by 20-30% compared to external systems.

It protects the machined hole from chip scratches, reducing post-processing steps like honing or polishing.

For manufacturers working with sticky materials (e.g., aluminum or copper), this system is even more critical—internal evacuation prevents chips from adhering to the hole wall and ruining the finish.

Why the Indexable Deep Hole Boring Head Is a Smart Investment

In today’s fast-paced manufacturing landscape, efficiency and precision are non-negotiable. The indexable deep hole boring head delivers on both: its replaceable inserts cut downtime, its rigid design ensures accuracy, and its internal chip evacuation solves deep hole machining’s biggest pain point. Whether you’re producing hydraulic cylinders, aerospace components, or medical devices, this tool adapts to your needs—reducing costs, improving part quality, and keeping your production line running smoothly.

For businesses looking to stay competitive in precision machining, adopting an indexable deep hole boring head isn’t just an upgrade—it’s a strategic choice to meet the demands of modern industry.

counter boring head is deep hole boring head other name, if you want to know more about deep hole counter boring head or indexable deep hole boring head, you can contact us email: sales@btadrilltools.com , or whatsapp +8618353452290