we sell deep hole drilling tools, Such as Deep hole drilling BTA drill head, gun driling tools, trepanining drill, deep hole skiving and roller burnishing tool deep hole drilling insert etc.

you can contact us sales@btadrilltools.com, whatsapp +8618353452290

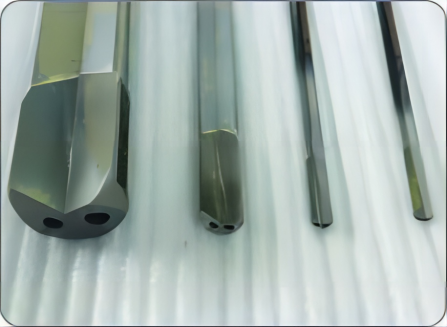

deep hole drills BTA drill head

Gundrilling drill head:

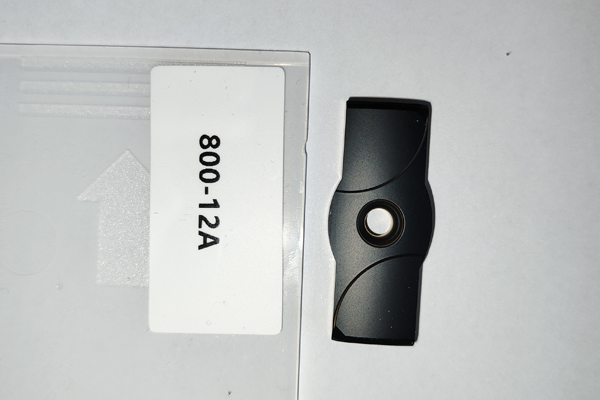

deep hole drilling insert:

guide pads:

trepanning drill

Skiving and roller burnishing tool

In the realm of modern manufacturing and engineering, deep hole drilling tools play a crucial role in achieving precision and efficiency. These specialized tools are designed to penetrate deep into various materials, opening up new possibilities for complex industrial processes.

they are crafted with precision and durability in mind. They are engineered to withstand the high pressures and intense forces encountered during deep hole drilling operations. Whether it’s drilling through metal, alloy, or other hard materials, these tools are up to the task.

deep hole drilling tools advantage:

One of the key advantages is their ability to create accurate and straight holes with a high degree of repeatability. This is essential for applications where tight tolerances are required, such as in the aerospace, automotive, and oil and gas industries.

The design often incorporates advanced features to enhance performance. For example, some tools are equipped with special coatings to reduce friction and wear, prolonging their lifespan and ensuring consistent drilling quality. Others may have unique geometries that optimize chip removal and prevent clogging.

In addition to their technical capabilities, it also offer economic benefits. By reducing machining time and improving productivity, they can help manufacturers save on costs and increase competitiveness.

As technology continues to advance, the development of deep hole drilling tools is also evolving. New materials and manufacturing processes are being explored to create even more efficient and reliable tools.

In conclusion, they are indispensable in today’s industrial landscape. Their precision, durability, and performance make them a valuable asset for manufacturers seeking to achieve high-quality results in their drilling operations. Whether it’s for large-scale production or specialized applications, these tools are sure to play a significant role in shaping the future of manufacturing.