Do you know what is guide pad for deep hole machine?

It is import component of deep hole drill head or deep hole tool.good guide pad can ensure deep hole machining quality and accuracy.

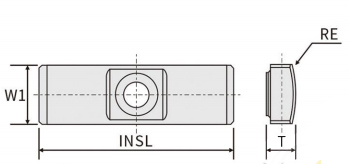

Let our see this picture:

Our company have rich and professional experience in the field of deep hole and years of deep hole machining knowledge, we have successfully developed a series of deep hole gun drilling tools and guide pad.

These cutting tools adopt a series of advanced processes, including procurement of imported raw materials, dry pressing forming, high-temperature sintering, passivation treatment, peripheral chamfering, and Balchals coating, to ensure high-quality guide pad processing results.

1. guide pad Selection and procurement of raw materials: The company carefully selects imported high-quality raw materials to provide a solid foundation for the manufacturing of deep hole gun drills. These raw materials provide reliable support for subsequent processes while ensuring tool performance.

2. Dry pressing forming: Using dry pressing forming process, fine raw material powder is formed through a mold to prepare for high-temperature sintering. This step ensures the accuracy of the overall structure and shape of the tool.

3. High temperature sintering: The high temperature sintering process is a key step in ensuring the density and hardness of tool materials. Through high temperature and pressure, raw material particles combine during the sintering process to form a sturdy tool matrix. This structure is crucial in the processing of guide pad and can withstand large workloads.

4. Passivation treatment: Passivation treatment improves the corrosion resistance of the cutting tool and prolongs its service life. When machining guide pad , the tool needs to have excellent durability, and passivation treatment effectively improves the tool’s durability.

5. Peripheral chamfering process: The processing of peripheral chamfering ensures the shape and quality of the cutting edge of the tool. This step is crucial for cutting effectiveness and tool lifespan, especially in high-precision tasks such as guide key machining.

6. Balchals coating: Balchals coating technology is applied to the surface of cutting tools, providing extremely high hardness, wear resistance, and high-temperature resistance. This advanced coating significantly improves the performance of the tool, enabling it to complete guide key machining tasks more efficiently.

The company’s deep hole gun drill series tools have excellent technical advantages and performance in the field of guide pad processing. By adopting production processes such as imported raw materials, dry pressing, high-temperature sintering, passivation treatment, peripheral chamfering, and Balchals coating, these cutting tools can meet the high requirements of guide key processing, improve processing efficiency and quality, and provide reliable support for industrial production.

We produce solid carbide and welding type , satisfy your need.

If you have any need and question for deep hole guide key, you can contact with email: sales@btadrilltools.com

| guide pad type | Diameter range | L | B | T |

| 800-06A | 25.00-31.00 | 18 | 6 | 3.0 |

| 800-07A | 31.01-39.60 | 20 | 7 | 3.5 |

| 800-08A | 39.61-47.00 | 25 | 8 | 4.5 |

| 800-10A | 47.01-54.99 | 30 | 10 | 4.5 |

| 800-12A | 55.00-65.00 | 35 | 12 | 5.5 |