The function of guide pad in deep hole machining cutters

Do you know the function of guide pad in deep hole machining cutters?

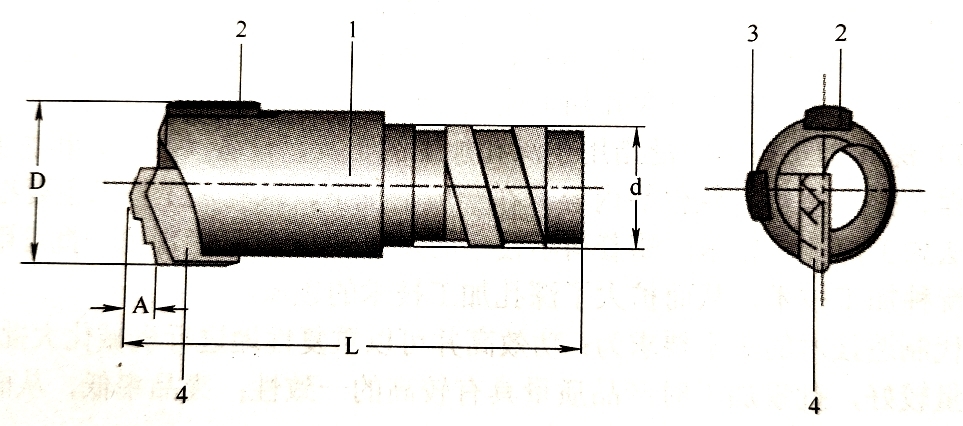

At this time, we have to know about self guiding principle meaning and their asymmetric structure. Figure 1-1 shows a deep hole cutter, which is a single-side cutting drill bit with an asymmetric structure. In the figure, 1 represents the BTA body, 2 and 3 are the guide pad, and 4 is the cutting edge (or blade). The guide pad 2 and 3 do not cut but contact the already machined surface of the deep hole, serving as guides.

To enhance wear resistance, they are typically made of cemented carbide. The two guide strips bear radial forces, and under the action of these forces, they maintain contact with the wall of the already machined deep hole during the machining process, moving along the hole wall towards the un machined portion.

Therefore, the direction of feed of the drill bit is determined by the wall of the already machined hole, achieving self-guidance of the drill bit. This function is called self-guiding. Tools with self-guiding capability are referred to as self-guided cutters.

Typical examples include BTA cutters and gun drill cutters. These types of drill bits use the wall of the already machined deep hole as a reference to achieve stable self-guidance, capable of machining deep holes with good straightness. The guide strips roll over the hole wall during deep hole machining, significantly reducing the surface roughness of the deep hole, which can reach Ra0.4-3.2μm (depending on the material being machined).

and we also sell customized deep hole drilling guide pad, if you need, contact us email: sales@btadrilltools.com