U DRILL CHOOSE AND GUIDE is for you, High efficiency indexable fast bit is our advantage drill hole product, it can machining workpiece with inner coolant more fast and more effiency. Below we named U drill or fast bit. and this drill head name is compare with deep hole drill, BTA deep hole drilling. More information please contact us, email: sales@btadrilltools.com

Let us know U drill feature:

- High quality bits can effectively reduce machining costs.

- The central cooling hole system helps prevent blade wear and improves cutting efficiency.

- The optimized chip holding groove increases the rigidity of cutter body and makes the chip discharge more smooth.

- It has both anti-breakage and wear resistance, and is suitable for various hole processing.

- Ensure excellent cutting performance and hole finish.

- The updated blade position angle makes cutting more efficient reduces machine load and improves blade life.

- Bit tolerance stability.

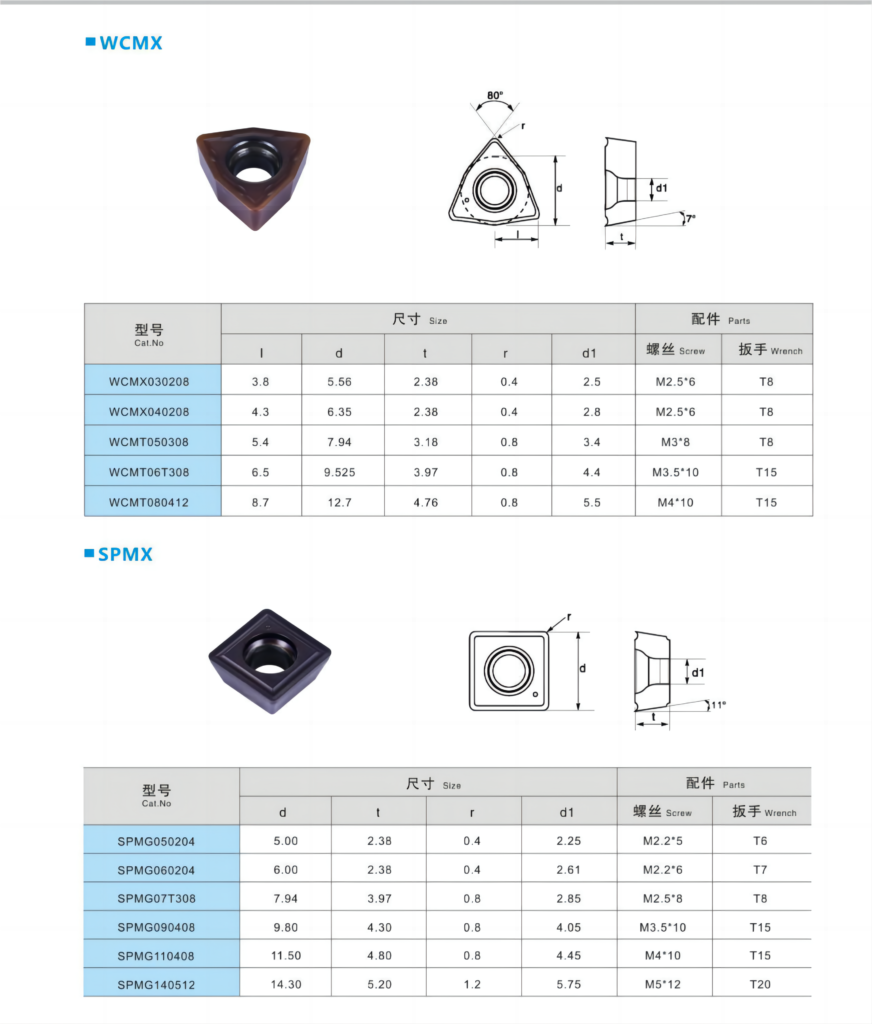

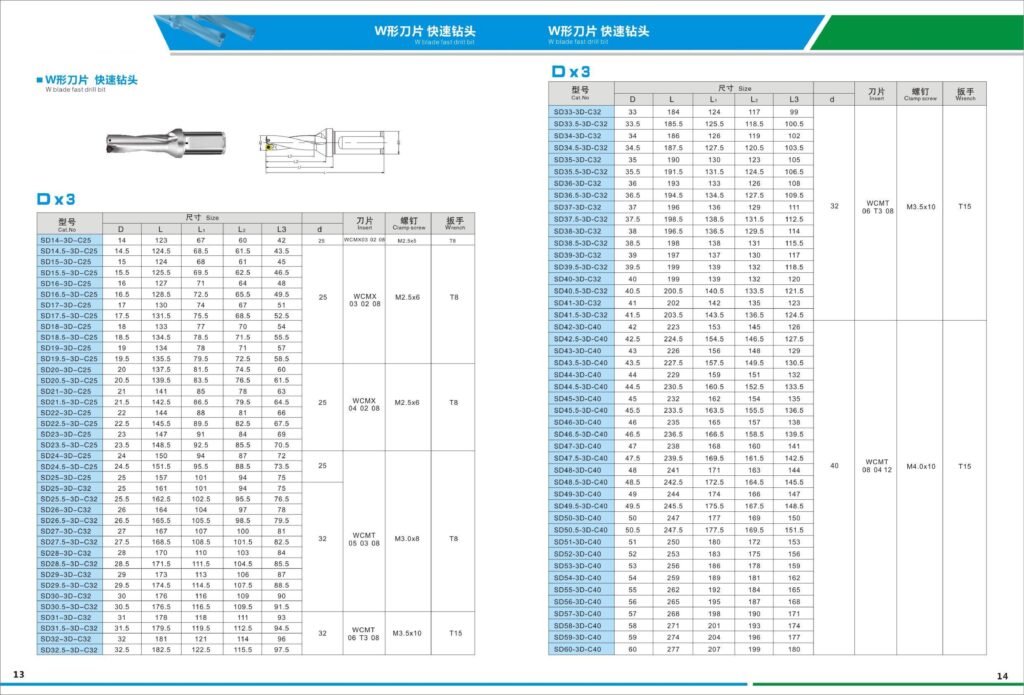

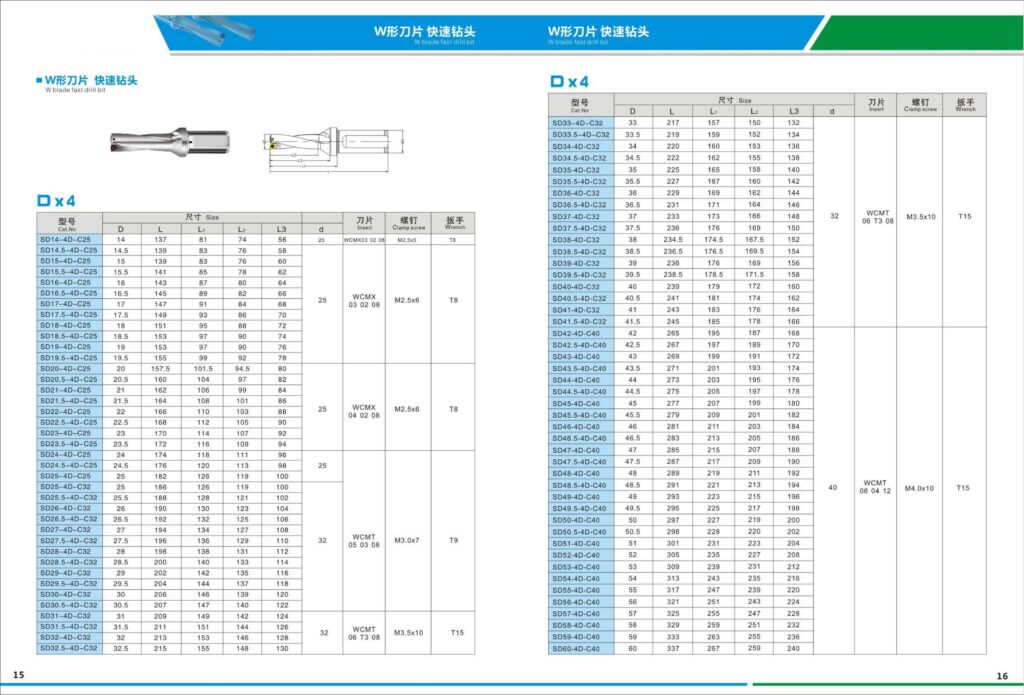

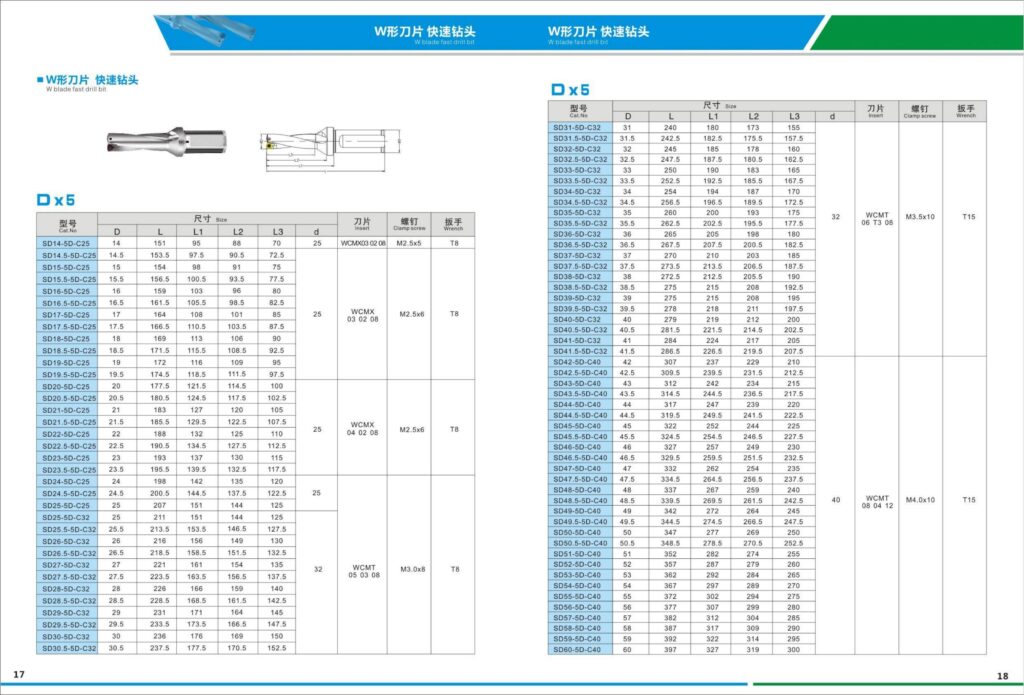

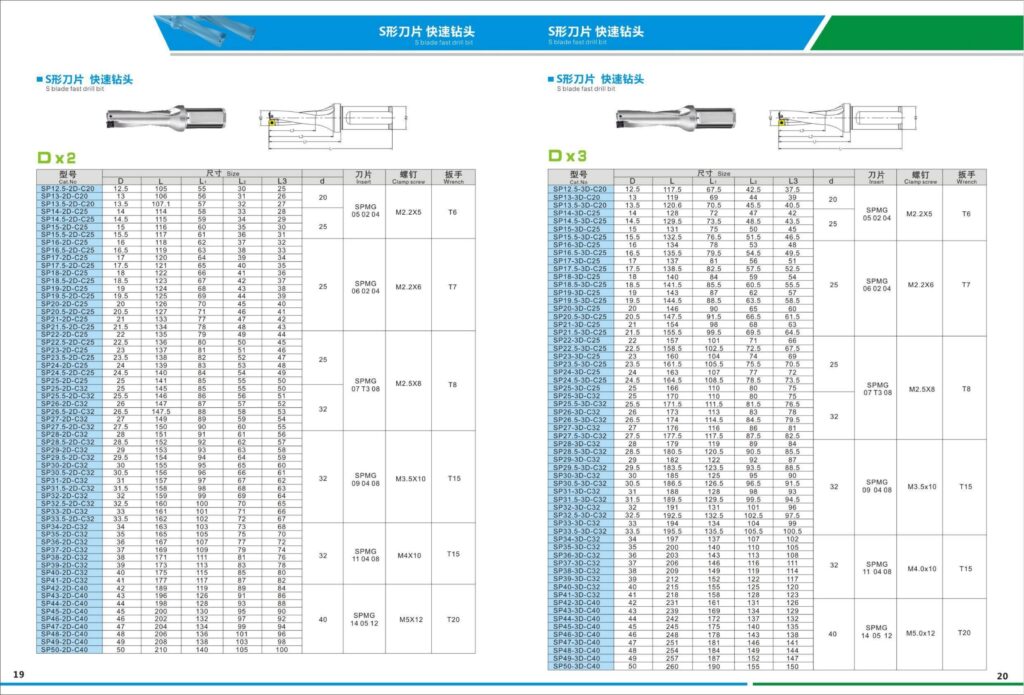

We have WC TYPE AND SP TYPE

Insert type WCMX \SPMX

Advantages of drilling:

First of all, the difference between the U drill and the ordinary drill is that the U drill uses the blade around the blade and the center blade. From this point of view, the relationship is almost the same as that between the machine clamp turning tool and the welding turning tool. After the tool is worn, the blade can be replaced without regrinding. After all, the use of indexable blades saves material than the overall hard drill, and the consistency of the blades is easier to control the part size.

When drill encounters various materials, it only needs to replace the blades of the same type and different brands. Hard drill is not so convenient.

Compared with the hard drill, the accuracy of the hole drilled by the U drill is still higher, and the smoothness is better, especially when the cooling and lubrication are not smooth, and the U drill can correct the position accuracy of the hole, but not the hard drill. You can use the U drill as an over-center bore knife.

Advantages of U drill in NC machining

It can drill holes on the surface with a slope angle less than 30~without reducing the cutting parameters.

After the cutting parameters of the U-drill are reduced by 30%, intermittent cutting can be realized, such as machining intersecting holes, intersecting holes and intersecting holes.

it can realize the drilling of multi-step holes, and can bore, chamfer and eccentric drill holes.

When drilling, the drilling chips are mostly short chips, and the internal cooling system can be used for safe chip removal without cleaning the chips on the tool, which is conducive to the continuity of product processing, shortening processing time and improving efficiency.

Under the condition of standard length-diameter ratio, there is no need to remove chips when drilling with U drill.

it is an indexable tool. The worn blade does not need to be sharpened. It is convenient to replace and the cost is low.

The surface roughness value of the hole processed by U-drill is small, and the tolerance range is small, which can replace the work of some boring cutters.

It is not necessary to pre-punch the center hole when using the drill, and the bottom surface of the blind hole processed is relatively straight, so the flat-bottomed drill bit is omitted.

The use of U-drill technology can not only reduce the number of drilling tools, but also because the adopts the way of inserting cemented carbide blade in the head, its cutting life is more than ten times of that of ordinary drill. At the same time, there are four cutting edges on the blade, which can be replaced at any time when the blade is worn. The new cutting saves a large amount of grinding and tool replacement time, and can increase the work efficiency by 6-7 times on average.