Generally, alloy steels containing more than 12% chromium or more than 8% nickel are referred to as stainless steel. Stainless steel can be classified by chemical composition into chromium stainless steel and chromium-nickel stainless steel. Based on metallurgical structure, it can be further divided into the following five major categories:

(1) Martensitic steel;

(2) Ferritic steel;

(3) Austenitic steel;

(4) Austenitic-ferritic steel;

(5) Precipitation hardening steel.

The machinability of stainless steel is very poor, making it a difficult-to-machine material. The difficulty of machining increases progressively among these five categories. Therefore, for cutting tools used on stainless steel, high heat resistance, good wear resistance, and minimal affinity with stainless steel are required.

High-speed steel tools should be made of high-performance high-speed steels such as high-carbon, molybdenum-containing, aluminum-containing, and high-vanadium types, which can greatly improve tool life. Recommended grades include 95W18Cr4V, W12Cr4V2Mo, W10Mo4Cr4V3Al, etc.

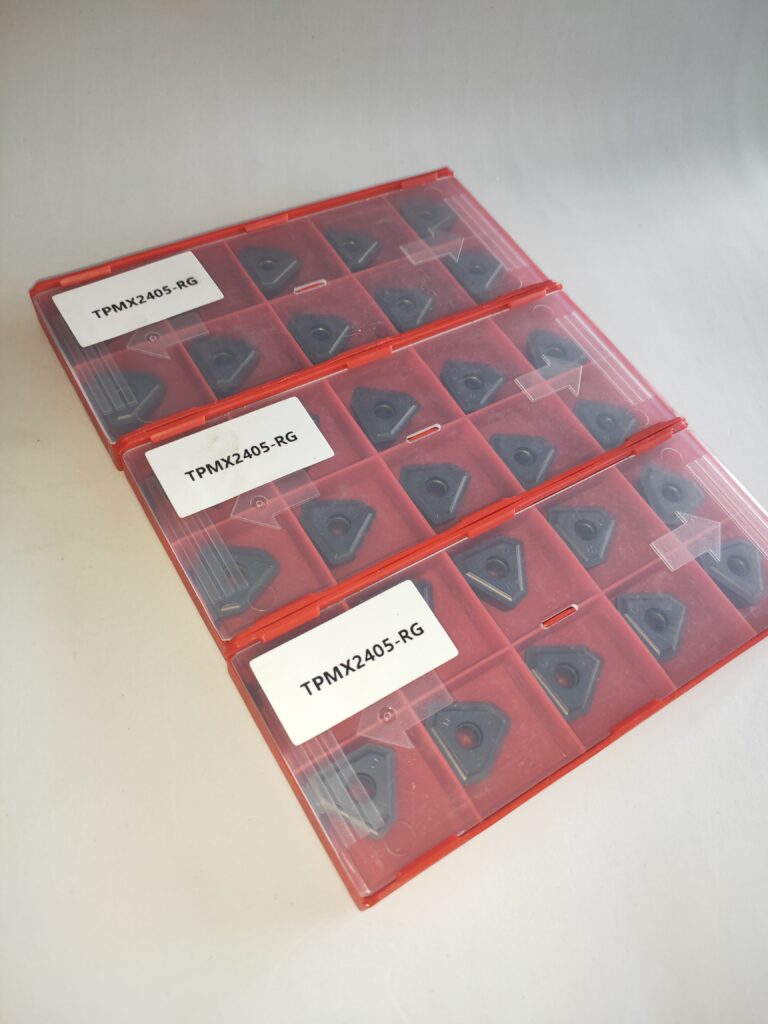

Cemented carbides should be selected from YG (K) or YW (M) types with fine or ultra-fine grains containing TaC or NbC, such as YG813, YS2, YS8, YW4, YD15, etc. These can reduce adhesive wear caused by affinity and also significantly enhance tool life. Coated cemented carbides can also be used for machining steel to further improve tool life.

Stainless steel presents notable challenges in machining due to its high tensile strength, work-hardening tendency, and poor thermal conductivity. These properties cause rapid tool wear, heat buildup, and dimensional inaccuracies. When drilling deep holes in stainless steel, several precautions are crucial. Use high-performance cutting tools like carbide or cobalt-coated bits to withstand heat and abrasion. Apply ample coolant to reduce friction and dissipate heat, preventing workpiece distortion. Maintain precise tool alignment to avoid deflection and ensure straight holes. Control feed rates and spindle speeds to balance material removal with tool longevity. Regularly check tool condition and implement peck drilling to clear chips, as clogged flutes can lead to tool breakage. Monitoring temperature and vibration levels also enhances process stability and hole quality.